how to select crushing equipment for limestone

AP42 Section Crushed Stone Processing and ...

Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about to centimeters (3/16th .

Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about to centimeters (3/16th .

Limestone Conveying System

Ground limestone has two primary functions. As fillers, ground limestone reduces the cost by replacing a portion of the asphalt. It also improves the physical performance properties of the shingles. Raw limestone is delivered by barge to the facility for processing. It is offloaded, stored, crushed, ground and dried.

Ground limestone has two primary functions. As fillers, ground limestone reduces the cost by replacing a portion of the asphalt. It also improves the physical performance properties of the shingles. Raw limestone is delivered by barge to the facility for processing. It is offloaded, stored, crushed, ground and dried.

Benefits of Pelletizing Limestone

Pelletized limestone, also known as pelletized lime, results from crushing limestone rock into a powder and then pelletizing the material. By undergoing pelletization, the product is easy to handle, while still maintaining the quickdissolving benefits found in powdered lime. Quicklime. Quicklime is created by heating limestone.

Pelletized limestone, also known as pelletized lime, results from crushing limestone rock into a powder and then pelletizing the material. By undergoing pelletization, the product is easy to handle, while still maintaining the quickdissolving benefits found in powdered lime. Quicklime. Quicklime is created by heating limestone.

Cone Crusher

Cone Crusher is suitable for crushing all kinds of ores and rocks with medium or above hardness. Compared with PY Series Spring Cone Crusher, it has the characteristics of reliable structure, high production efficiency, and convenient adjustment. It is the most ideal equipment that suitable for crushing hard, medium hardness above all ...

Cone Crusher is suitable for crushing all kinds of ores and rocks with medium or above hardness. Compared with PY Series Spring Cone Crusher, it has the characteristics of reliable structure, high production efficiency, and convenient adjustment. It is the most ideal equipment that suitable for crushing hard, medium hardness above all ...

(PDF) Design of a Material Handling Equipment: Belt ...

· Design of a Material Handling Equipment: Belt Conveyor System for Crushed Limestone Using 3 roll Idlers I. A. Daniyan *, A. O. Adeodu and O. M. Dada Department of Mechanical Mechatronics ...

· Design of a Material Handling Equipment: Belt Conveyor System for Crushed Limestone Using 3 roll Idlers I. A. Daniyan *, A. O. Adeodu and O. M. Dada Department of Mechanical Mechatronics ...

Blog |

Coal Crushing: Newtype Toothed Roll Crusher VS Traditional Toothed Roll Crusher. Toothed roll crusher is widely used in the coal industry and engineers have upgraded and optimized it in several aspects, please find more details in this article. Steven. Nov 08,2019. read more.

Coal Crushing: Newtype Toothed Roll Crusher VS Traditional Toothed Roll Crusher. Toothed roll crusher is widely used in the coal industry and engineers have upgraded and optimized it in several aspects, please find more details in this article. Steven. Nov 08,2019. read more.

Kinglink Crusher for Aggregates and Mining

crushing operations. Kinglink's expertise and technology in crushing, screening and conveying help you save time, energy and money. Our experts work with you as a partner to determine the best process and equipment for your specific needs. SANDMAKING. Supports coarse,medium,fine and ultrafine. crushing operations.

crushing operations. Kinglink's expertise and technology in crushing, screening and conveying help you save time, energy and money. Our experts work with you as a partner to determine the best process and equipment for your specific needs. SANDMAKING. Supports coarse,medium,fine and ultrafine. crushing operations.

Crusher Manufacturers in India | – Stationary ...

· Stone crushing equipment has become increasingly popular in recent years, ... However, the operator selecting the crusher requires choosing the crusher type which would suit the industry's requirement. ... To crush the hard materials in the chemical industry like limestone, coal, coke, slag jaw crusher is used widely.

· Stone crushing equipment has become increasingly popular in recent years, ... However, the operator selecting the crusher requires choosing the crusher type which would suit the industry's requirement. ... To crush the hard materials in the chemical industry like limestone, coal, coke, slag jaw crusher is used widely.

Choosing the right crusher

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks ...

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks ...

Product List

This type of reinforced jaw crusher is the first choice of high efficiency coarse crushing equipment for quarry rocks and minerals. Read More. CS Highefficiency Cone Crusher Capacity:20600T/H. CS cone crusher is a improved machine of PY series cone crusher.

This type of reinforced jaw crusher is the first choice of high efficiency coarse crushing equipment for quarry rocks and minerals. Read More. CS Highefficiency Cone Crusher Capacity:20600T/H. CS cone crusher is a improved machine of PY series cone crusher.

Mobile Crusher Plants

Mobile crushers can be installed in desired places and cost rate is lower instead of fixed plants and these advantages preferred reason to choose mobile crushers nowadays. Highly engineered mobile systems are assembled on a single mobile chassis with all their components, and provides easy maintanance and repair.

Mobile crushers can be installed in desired places and cost rate is lower instead of fixed plants and these advantages preferred reason to choose mobile crushers nowadays. Highly engineered mobile systems are assembled on a single mobile chassis with all their components, and provides easy maintanance and repair.

Secondary Crusher

· Jaw Crusher Overview. Jaw Crusher is one of the main types of primary crushers in a mine or ore processing crusher plant and also is one of the most widely used crushing equipment in mining industry. This series of jaw crusher can reach the crushing ratio of 46 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for .

· Jaw Crusher Overview. Jaw Crusher is one of the main types of primary crushers in a mine or ore processing crusher plant and also is one of the most widely used crushing equipment in mining industry. This series of jaw crusher can reach the crushing ratio of 46 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for .

Should know all about Stone Crusher Plant

In the market, various kind of crusher plant is there and used in different industries for fulfilling the crushing needs but here we will talk all about the stone crusher stone crusher plant is working, what are the stone crusher machine is available in the market.

In the market, various kind of crusher plant is there and used in different industries for fulfilling the crushing needs but here we will talk all about the stone crusher stone crusher plant is working, what are the stone crusher machine is available in the market.

Crushing Plant Equipment | Fleet Of Crushing, Grinding And ...

Milling crushers are the machines used to shred feed materials into fine materials. The list of materials that hammer mill crushers turn into fine particles includes milling grain, corns, livestock, etc.. A hammer mill machine is a steel drum that has vertical or horizontal rotary shaft or drum on which hammers are attached.

Milling crushers are the machines used to shred feed materials into fine materials. The list of materials that hammer mill crushers turn into fine particles includes milling grain, corns, livestock, etc.. A hammer mill machine is a steel drum that has vertical or horizontal rotary shaft or drum on which hammers are attached.

Case Study: Crusher Dust Control at Limestone Mine ...

· The crushed material is then put on the surge pile where it is taken to the secondary crushing plants on the site to be reduced down to a variety of sizes. Mining dust control. In the past, Linwood has used water hoses and spray bars to help control dust both at the crusher .

· The crushed material is then put on the surge pile where it is taken to the secondary crushing plants on the site to be reduced down to a variety of sizes. Mining dust control. In the past, Linwood has used water hoses and spray bars to help control dust both at the crusher .

Preventive Maintenance Scheduling by Modularity Design ...

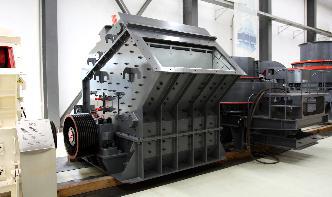

· In this study, limestone crusher machine is used with the type of Impact Hammer Crusher. The capacity of the machines used in the amount of 1300 tons per Hours. An important engine part on limestone crusher machine that is part of the initial material or hopper receiver, motor or drive system, material feeding section or feeder.

· In this study, limestone crusher machine is used with the type of Impact Hammer Crusher. The capacity of the machines used in the amount of 1300 tons per Hours. An important engine part on limestone crusher machine that is part of the initial material or hopper receiver, motor or drive system, material feeding section or feeder.

2 Types of Concrete Crushers |

· 2. According to the function, it is divided into crushing type and sand making type: the concrete crushing and screening machine includes a combination of crushing equipment such as jaw crusher, cone crusher and impact crusher. The sand making type is mainly equipped with sand making machine and hammer sanding machine.

· 2. According to the function, it is divided into crushing type and sand making type: the concrete crushing and screening machine includes a combination of crushing equipment such as jaw crusher, cone crusher and impact crusher. The sand making type is mainly equipped with sand making machine and hammer sanding machine.

The Benefits of Cubical Aggregate | AsphaltPro Magazine ...

The crushers are the determinant of the percent cubical aggregate processed. The best option is to feed crushed, cubical material to the screen, and let the screen decks size the different particles into the desired cubical gradations. The crusher needs to be the device that controls the amount of elongated product in the feed, not the screen.

The crushers are the determinant of the percent cubical aggregate processed. The best option is to feed crushed, cubical material to the screen, and let the screen decks size the different particles into the desired cubical gradations. The crusher needs to be the device that controls the amount of elongated product in the feed, not the screen.

Limestone Crusher

After secondary crushing, those materials were sent to circular vibrating screen for screening out the required products, and the unqualified products are transferred to impact crusher for recrushing. Final products size: 040mm. Capacity: 550650tph. Equipment: Vibrating Feeder GZD1500×6000, PE Series Jaw Crusher PE1200×1500, European Type ...

After secondary crushing, those materials were sent to circular vibrating screen for screening out the required products, and the unqualified products are transferred to impact crusher for recrushing. Final products size: 040mm. Capacity: 550650tph. Equipment: Vibrating Feeder GZD1500×6000, PE Series Jaw Crusher PE1200×1500, European Type ...

Crusher Gearboxes

Crusher Gearboxes In crushing processes for limestone, brick, and coal, the bevel gears used in vertical crushers are not only subjected to tremendous impact loads and environmental loads, they must also exhibit a high degree of efficiency in order to reliably provide continuous power transmission that is guaranteed by Klingelnberg machines.

Crusher Gearboxes In crushing processes for limestone, brick, and coal, the bevel gears used in vertical crushers are not only subjected to tremendous impact loads and environmental loads, they must also exhibit a high degree of efficiency in order to reliably provide continuous power transmission that is guaranteed by Klingelnberg machines.

الوظائف ذات الصلة

- الجهاز 200 شبكة لطحن الباريت

- أغراض حجرية باردة للبيع

- عملية المبدأ من التدعيم

- كسارة النقالة المستعملة للبيع المملكة العربية السعودية

- كيفية جعل سحق الصخور الصغيرة

- تصنيع كسارة سلسلة

- شركة التعدين والبناء المحدودة الصين

- بناء الهيدروليكي الحجر الألغام مخروط محطم

- يرغبون في شراء كسارة حجر في بوبال

- الفلسبار 200 شبكة الكرة مستمرة مطحنة

- stone crushing equipment in india for sale

- small crusher in for sale in mumbai

- hydrolic concrete crusher others

- high crushing ratio antimony ore crusher price with competitive price

- roller mills all blacks

- louisiana mines for sale

- safe use of grinding machine

- machine for cement plant

- angle grinders quality price

- prices and sizes of crusher

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher