jaw crusher in cheek plate designs

PEW400×600 Jaw Plates | Wear Parts For Industry | Qiming ...

When it comes to PEW400×600 jaw plates, Qiming Casting had manufactured those wear parts for Canadian customers.

When it comes to PEW400×600 jaw plates, Qiming Casting had manufactured those wear parts for Canadian customers.

Wear Parts for Cone and Jaw Crushers

zNew ST jaw plates for large crushers zOne piece zAngled teeth to reduce cheek plate wear. Quarry Academy 2005 Study of Wear Profiles zHeavy Duty (HD) zWide Teeth (WT), Z zPlease report to Crushing Technology Group. Quarry Academy 2005 Manganese steel ...

zNew ST jaw plates for large crushers zOne piece zAngled teeth to reduce cheek plate wear. Quarry Academy 2005 Study of Wear Profiles zHeavy Duty (HD) zWide Teeth (WT), Z zPlease report to Crushing Technology Group. Quarry Academy 2005 Manganese steel ...

Computer Aided Design and Finite Element Analysis of Swing ...

facilitates for quick design of the plates of the jaw crusher. The different comparisons of corrugated swing jaw plates behavior, calculated with the traditional and the new FEA failure models with stiffeners, shows that some 1025% savings in plate weight may be possible. Key Words: Jaw ...

facilitates for quick design of the plates of the jaw crusher. The different comparisons of corrugated swing jaw plates behavior, calculated with the traditional and the new FEA failure models with stiffeners, shows that some 1025% savings in plate weight may be possible. Key Words: Jaw ...

Jaw crushers and plates

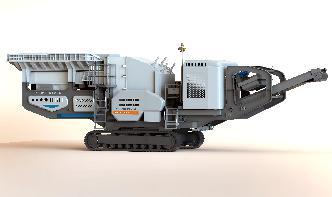

Jaw crushers and plates Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Jaw crushers and plates, quarry, aggregate, and different kinds of minerals.

Jaw crushers and plates Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Jaw crushers and plates, quarry, aggregate, and different kinds of minerals.

Jaw Crusher Cheek Plates

Jaw Crusher Cheek Plates. Description M ES offers the cheek plate s for , jaw crushers, made of high manganese castings, longer endurance, good performance, with good competitive price.. Product name: jaw crusher cheek plates. Model: CJ/C series wear part. Type: wear part. Material: high manganese steel

Jaw Crusher Cheek Plates. Description M ES offers the cheek plate s for , jaw crushers, made of high manganese castings, longer endurance, good performance, with good competitive price.. Product name: jaw crusher cheek plates. Model: CJ/C series wear part. Type: wear part. Material: high manganese steel

Design and Finite Element Analysis of Swing Jaw Plate of ...

Design of lighter weight jaw crushers will require a more precise accounting of the stresses and deflections in the crushing plates than is available with traditional techniques. Efforts to decrease energy consumed in crushing have lead to consideration of decreasing the weight of the swing plate of jaw crushers for easily crushed material.

Design of lighter weight jaw crushers will require a more precise accounting of the stresses and deflections in the crushing plates than is available with traditional techniques. Efforts to decrease energy consumed in crushing have lead to consideration of decreasing the weight of the swing plate of jaw crushers for easily crushed material.

Crusher Wear Parts Selection Guide (External) 001

JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws Cheek Plates CSS Feed Opening C2, C3 C4 Mantle Bowl Liners CSS Feed Opening C38 C44 Mantle Bowl Liners Blow Bars Selection Blow Bars Curtain Liners CONTENTS 0205 0608 0910 1112

JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws Cheek Plates CSS Feed Opening C2, C3 C4 Mantle Bowl Liners CSS Feed Opening C38 C44 Mantle Bowl Liners Blow Bars Selection Blow Bars Curtain Liners CONTENTS 0205 0608 0910 1112

Jaw Plate YR0018

First of all, we will collect all information about the issue parts, such as the casting number, pictures and the working condition to figure out the real reason why the products happened issue. Then, our engineer will trace the production records according to the casting number, and analyzing the casting sample again we kept, the pictures will ...

First of all, we will collect all information about the issue parts, such as the casting number, pictures and the working condition to figure out the real reason why the products happened issue. Then, our engineer will trace the production records according to the casting number, and analyzing the casting sample again we kept, the pictures will ...

Cheek Plates | Jaw Crusher Parts | HANDY

Cheek plate model: Various models Order quantity/pcs: Not limited The crusher spares are perfect for the jaw crushers which are widely used in mining, smelting, building materials, road construction, railway construction, water conservancy and chemical industries for crushing various ores and bulky materials into medium grain size.

Cheek plate model: Various models Order quantity/pcs: Not limited The crusher spares are perfect for the jaw crushers which are widely used in mining, smelting, building materials, road construction, railway construction, water conservancy and chemical industries for crushing various ores and bulky materials into medium grain size.

Computer Aided Design and Analysis of Swing Jaw Plate of ...

quick design of the plates of the jaw crusher. The different comparisons of corrugated swing jaw plates behavior, calculated with the traditional and the new FEA failure models with stiffeners, shows that some 1025% savings in plate weight may be possible.

quick design of the plates of the jaw crusher. The different comparisons of corrugated swing jaw plates behavior, calculated with the traditional and the new FEA failure models with stiffeners, shows that some 1025% savings in plate weight may be possible.

JAQUES

• Machined jaw liner support cheek plates • Curved fixed and moving jawface liners • Provides optimum nip angle in fine crushing zone • Lifting points cast into jaw liners • Bolt and tapered nut retention of fixed jaws • Bolted retention of moving jaws • Replaceable jaw backing plates • Robust swing jaw design

• Machined jaw liner support cheek plates • Curved fixed and moving jawface liners • Provides optimum nip angle in fine crushing zone • Lifting points cast into jaw liners • Bolt and tapered nut retention of fixed jaws • Bolted retention of moving jaws • Replaceable jaw backing plates • Robust swing jaw design

crusher cheek plates

Cheek Plates Jaw Crusher Parts Tensalloy™ AR500 Steel. Cheek Plates Jaw Crusher Parts Download Brochure. The cheek plates lining the inside of the jaw crusher cavity are subject to both high stress (during the crushing cycle) and low stress (between crushing cycles) abrasion. This abrasion wears away the material from which the cheek plates ...

Cheek Plates Jaw Crusher Parts Tensalloy™ AR500 Steel. Cheek Plates Jaw Crusher Parts Download Brochure. The cheek plates lining the inside of the jaw crusher cavity are subject to both high stress (during the crushing cycle) and low stress (between crushing cycles) abrasion. This abrasion wears away the material from which the cheek plates ...

Design Jaw Plate Crusher

Design Jaw Plate Crusher. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. Products crusher jaw plates design.

Design Jaw Plate Crusher. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. Products crusher jaw plates design.

Jaw Crusher Cheek Plate Designs

Design And Construction Of Rock Crushing Machine From. Cheek plates the positioning of these plates on the jaw crusher justifies the name cheek plates they are made or coated with high strength manganese steel for durability purpose as it can be seen in the assembly drawing the design is done in such a way as to act as additional lock to key down the fixed jaw to its stock figure

Design And Construction Of Rock Crushing Machine From. Cheek plates the positioning of these plates on the jaw crusher justifies the name cheek plates they are made or coated with high strength manganese steel for durability purpose as it can be seen in the assembly drawing the design is done in such a way as to act as additional lock to key down the fixed jaw to its stock figure

Real Steel – Crusher Parts — Real Steel

Jaw Crushers. We offer a wide range of jaws, cheek plates and supplemental parts for all brands of jaw crusher. Our cast cheek plates are made from 13% Manganese and 2% chrome iron. Our crusher jaws are cast from 18% Manganese 3% Chrome iron. We also custom design jaws that offer increased performance using ultra heavy duty 21% Manganese and 2% ...

Jaw Crushers. We offer a wide range of jaws, cheek plates and supplemental parts for all brands of jaw crusher. Our cast cheek plates are made from 13% Manganese and 2% chrome iron. Our crusher jaws are cast from 18% Manganese 3% Chrome iron. We also custom design jaws that offer increased performance using ultra heavy duty 21% Manganese and 2% ...

Australian Crushing and Mining

All our jaw plates are stocked in 1820% grades of manganese, in the most popular profiles including standard, quarry, super tooth, recycling and corrugated. We also stock a wide range of replacement parts for these machines, including toggle seats, toggle plates, and a wide range of cheek plates, wedges, nuts, bolts and washers.

All our jaw plates are stocked in 1820% grades of manganese, in the most popular profiles including standard, quarry, super tooth, recycling and corrugated. We also stock a wide range of replacement parts for these machines, including toggle seats, toggle plates, and a wide range of cheek plates, wedges, nuts, bolts and washers.

Jaw Plate Materials | Crusher Mills, Cone Crusher, Jaw ...

Jaw crusher cheek plate materials. These cheek plates are made out of abrasion resistant materials. They are fixed to the sides of the main body to protect it from wear. jaw crusher jaw plate material, ... design of teeth of jaw plates for for crushing abrasive ...

Jaw crusher cheek plate materials. These cheek plates are made out of abrasion resistant materials. They are fixed to the sides of the main body to protect it from wear. jaw crusher jaw plate material, ... design of teeth of jaw plates for for crushing abrasive ...

Grey Hawk Design Fabriion | GHC116 Jaw Portable Plant

The toggle plate operates on a rocking principle without any lubriion and serves as an overload fuse. The crusher's jaw dies are of highmanganese steel castings, and the cheek plates of high abrasiveresistant steel plate. The jaw dies can be reversed for maximum utilization. Tools for jaw die changes are included with the jaw crusher.

The toggle plate operates on a rocking principle without any lubriion and serves as an overload fuse. The crusher's jaw dies are of highmanganese steel castings, and the cheek plates of high abrasiveresistant steel plate. The jaw dies can be reversed for maximum utilization. Tools for jaw die changes are included with the jaw crusher.

Analysis of the Single Toggle Jaw Crusher Force ...

Today, the most commonly used types of jaw crusher are the single toggle and the double toggle designs. The original double toggle jaw crusher was designed by Eli Whitney Blake in the USA in 1857 . The motion of the swing jaw in a double toggle crusher is such that it applies an almost purely compressive force upon the material being crushed.

Today, the most commonly used types of jaw crusher are the single toggle and the double toggle designs. The original double toggle jaw crusher was designed by Eli Whitney Blake in the USA in 1857 . The motion of the swing jaw in a double toggle crusher is such that it applies an almost purely compressive force upon the material being crushed.

HiPro Series Primary Jaw Crusher

Cheek Plates: Two Piece Geometry for Easy Handling; Deflector Plate: Hardened Alloy Steel Casting for Additional Protection against Wear . Hydraulic CSS Adjustment: Supplied as Standard in all HiPro Series Primary Jaw Crushers. Toggle Plate and Toggle Bearings: Machined and Hardened Castings. Lubriion Free Design.

Cheek Plates: Two Piece Geometry for Easy Handling; Deflector Plate: Hardened Alloy Steel Casting for Additional Protection against Wear . Hydraulic CSS Adjustment: Supplied as Standard in all HiPro Series Primary Jaw Crushers. Toggle Plate and Toggle Bearings: Machined and Hardened Castings. Lubriion Free Design.

Crushing and screening solutions

Jaw crushers ® C Series™ 4 rock breakers 18 Impact crushers ... lifetime of the crusher. These designs protect the most expensive main components from wear and ... lifting tools for jaw dies and cheek plates. In addition, an optional Maintenance platform makes

Jaw crushers ® C Series™ 4 rock breakers 18 Impact crushers ... lifetime of the crusher. These designs protect the most expensive main components from wear and ... lifting tools for jaw dies and cheek plates. In addition, an optional Maintenance platform makes

Crusher spare parts Jaw and cheek plate lifting tools

Jaw plate lifting tool (Double chain) C80, C95, C96, C100, C105, C106, C125 1500 KG C110, C116, C120, C130, C140, C145, C150, C160, C3054, C3055 2800 KG C200 5500 KG Our crusher wear part lifting tools are designed with OEM expertise, making them the best choice to remove jaw and cheek plates from your Outotec crushers.

Jaw plate lifting tool (Double chain) C80, C95, C96, C100, C105, C106, C125 1500 KG C110, C116, C120, C130, C140, C145, C150, C160, C3054, C3055 2800 KG C200 5500 KG Our crusher wear part lifting tools are designed with OEM expertise, making them the best choice to remove jaw and cheek plates from your Outotec crushers.

C Series jaw crushers

group, has installed over 10 000 jaw crushers since the 1920s. Today the C Series is indisputably the world's favourite jaw crusher. Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge. All C Series jaw crushers are based on a

group, has installed over 10 000 jaw crushers since the 1920s. Today the C Series is indisputably the world's favourite jaw crusher. Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge. All C Series jaw crushers are based on a

Crushing and screening solutions

Jaw crushers . ® C Series™ 4 rock breakers 18. Impact crushers ... ifting tools for jaw dies, cheek plates and toggle plate as standard Optional flywheel and drive guards ... lifetime of the crusher. These designs protect the most expensive main components from wear and

Jaw crushers . ® C Series™ 4 rock breakers 18. Impact crushers ... ifting tools for jaw dies, cheek plates and toggle plate as standard Optional flywheel and drive guards ... lifetime of the crusher. These designs protect the most expensive main components from wear and

الوظائف ذات الصلة

- محطم الفحم المصنوعات

- شاشات بيرلايت تهتز للبيع

- المصنعين مطحنة الكرة في الجزائر

- آلة محطم المسارات

- أنواع مصانع غسيل تعدين الذهب

- شراء كسارة الصابورة المستخدمة

- مصنع معالجة المعادن في ولاية ogun

- جهة ثانية حصان مخروط محطم

- أفضل تأثير محطم

- مطحنة الطوابع تصنع في الجزائر

- hpc series crushers

- crushing stone machine worldcrushers

- coal fired straight grate iron ore induration

- de rodillos en colombia

- equipments for concrete crushing

- xylene production from coal

- shanghai boxes suitable crusher

- por le limestone jaw crusher for hire in indonessia

- is manufacture definition and meaning

- cement mill process pdf in tamil language

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher