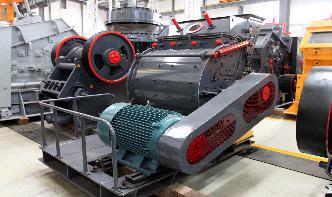

ball mill pestle impact grinder

Influence Factors of the Ball Mill in the Process of Grinding

· Influence Factors of the Ball Mill in the Process of Grinding. 09:36:12 XinHai (2494) Beneficiation ball mill has three influence factors in the grinding process with medium, including the ore properties, the structure of and the operation conditions of the machines.

· Influence Factors of the Ball Mill in the Process of Grinding. 09:36:12 XinHai (2494) Beneficiation ball mill has three influence factors in the grinding process with medium, including the ore properties, the structure of and the operation conditions of the machines.

Page 1 Ball Milling Theory

involve grinding). With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

involve grinding). With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

Ball Mill

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL .

size distributions and mill scale—up, they have not addressed the primary role of grinding, liberation. I The present investigation analyzes the effect of ball U mill operating· parameters on the breakage rates of both t· liberated and composite material. The operating parameters studied include mill rotational speed, ball size, mill I

size distributions and mill scale—up, they have not addressed the primary role of grinding, liberation. I The present investigation analyzes the effect of ball U mill operating· parameters on the breakage rates of both t· liberated and composite material. The operating parameters studied include mill rotational speed, ball size, mill I

INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES TO .

Effects of grinding media shapes on ball mill performance. Master of Science in Engineering University of the Witwatersrand, Johannesburg South Africa, 18 .

Effects of grinding media shapes on ball mill performance. Master of Science in Engineering University of the Witwatersrand, Johannesburg South Africa, 18 .

Analysis on Grinding media Motion in Ball Mill by Discrete ...

Keywords: Discrete Eelement Method (DEM),Ball mill,Grinding media motion,Simulation 1 Introduction Ball mills are extensively used in mining, construction, metallurgy, chemistry, power, etc. However, the motion state of practical charge (material and grinding media) is too complied to be described precisely.

Keywords: Discrete Eelement Method (DEM),Ball mill,Grinding media motion,Simulation 1 Introduction Ball mills are extensively used in mining, construction, metallurgy, chemistry, power, etc. However, the motion state of practical charge (material and grinding media) is too complied to be described precisely.

How to reduce the influence of high temperature on the ...

Due to the impact of grinding minerals, the mechanical friction energy of the grinding materials and the energy released when the materials are broken, the temperature of the ball mill is too high, and the high temperature in summer, the working environment is even as .

Due to the impact of grinding minerals, the mechanical friction energy of the grinding materials and the energy released when the materials are broken, the temperature of the ball mill is too high, and the high temperature in summer, the working environment is even as .

Sample Grinder at Thomas Scientific

MicroMill® Grinders. SP BelArt. .limestone, pharmaceuticals, pigment blends, plastics, rocks, roots, shale, seeds, slags, soil, teeth, wood, etc. To provide safety and prevent sample loss, the grinder operates only when the cover is latched in place. Supplied with a (6ft) 3 .

MicroMill® Grinders. SP BelArt. .limestone, pharmaceuticals, pigment blends, plastics, rocks, roots, shale, seeds, slags, soil, teeth, wood, etc. To provide safety and prevent sample loss, the grinder operates only when the cover is latched in place. Supplied with a (6ft) 3 .

Miller™ Tungsten Carbide Grinding Jars of Lab Ball Mill ...

Its density is about /cm3, twice that of stainless steel. We recommend our customers to use a larger size plenatary ball mill for tungsten carbide grinding jars. For example, the weight of a 500ml carbide grinding jar is about, we recommend to use in 4L planetary ball mill instead of 2L planetary ball mill, otherwise it is overloaded.

Its density is about /cm3, twice that of stainless steel. We recommend our customers to use a larger size plenatary ball mill for tungsten carbide grinding jars. For example, the weight of a 500ml carbide grinding jar is about, we recommend to use in 4L planetary ball mill instead of 2L planetary ball mill, otherwise it is overloaded.

The specific selection function effect on clinker grinding ...

The specific selection function effect on clinker grinding . efficiency in a dry batch ball mill . D. Touil a, S. Belaadi a, C. Frances b, 1 (a) Laboratoire de Génie de la Réaction, FGMGP, USTHB, BP 32 ElAlia, 16000 . Alger, Algérie (b) Laboratoire de Génie Chimique, UMR CNRS 5503, ENSIACET, 5 rue Paulin Talabot, 31106 Toulouse Cedex 01 ...

The specific selection function effect on clinker grinding . efficiency in a dry batch ball mill . D. Touil a, S. Belaadi a, C. Frances b, 1 (a) Laboratoire de Génie de la Réaction, FGMGP, USTHB, BP 32 ElAlia, 16000 . Alger, Algérie (b) Laboratoire de Génie Chimique, UMR CNRS 5503, ENSIACET, 5 rue Paulin Talabot, 31106 Toulouse Cedex 01 ...

Crushing Grinding Equipment | Sepor, Inc

The Micro Mill is a high frequency vibrating ball mill, with built in air sweep injectors to fluidize the bed of material to be ground. The air injected into the mill allows fine grinding to occur in a mill without having to wet grind. ... Cast Iron or Agate Mortar Pestle.

The Micro Mill is a high frequency vibrating ball mill, with built in air sweep injectors to fluidize the bed of material to be ground. The air injected into the mill allows fine grinding to occur in a mill without having to wet grind. ... Cast Iron or Agate Mortar Pestle.

Grinder | SigmaAldrich

MicroMill ™ grinder, blade, grinding chamber and timer. ... Steel vial and ball pestle for analog WigLBug ® grinder/mixer. Product Number Product Description; Z111554: stainless steel, diam. × L 1/2 in. × in. Pricing: ... IKA ® MF impact grinding head. IKA ...

MicroMill ™ grinder, blade, grinding chamber and timer. ... Steel vial and ball pestle for analog WigLBug ® grinder/mixer. Product Number Product Description; Z111554: stainless steel, diam. × L 1/2 in. × in. Pricing: ... IKA ® MF impact grinding head. IKA ...

Evolution of Laboratory Mills and Grinders | Lab Manager

Evolution of Laboratory Mills and Grinders. The process of grinding and milling is essential in many laboratory situations. Certain solventfree reactions are conducted, for example, by the fine grinding of reagents together in a vessel to ensure close contact of individual particles. April 6, 2011. John Buie.

Evolution of Laboratory Mills and Grinders. The process of grinding and milling is essential in many laboratory situations. Certain solventfree reactions are conducted, for example, by the fine grinding of reagents together in a vessel to ensure close contact of individual particles. April 6, 2011. John Buie.

BioSpec Products • Tissue Grinders

Tissue grinders disperse and disrupt small tissue samples by being repeatedly pressed or squeezed between two hard surfaces. Usually, one surface is concaveshaped (the mortar) and other convex (the pestle). The mortar can also be shaped to the geometry of the testtube, in which case the pestle is tight fitting with a clearance of mm between the inner walls of .

Tissue grinders disperse and disrupt small tissue samples by being repeatedly pressed or squeezed between two hard surfaces. Usually, one surface is concaveshaped (the mortar) and other convex (the pestle). The mortar can also be shaped to the geometry of the testtube, in which case the pestle is tight fitting with a clearance of mm between the inner walls of .

Ball Mills

Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

Particle size reduction, screening and size analysis ...

Impact mills use revolving hammers to strike incoming particles and to break or fling them against ... Mortar and pestle grinding can be accomplished with either manual or automated systems. ... Schematic representation of the crushing mechanism in a ball mill In wet grinding, the surrounding medium is liquid, as opposed to dry grinding.

Impact mills use revolving hammers to strike incoming particles and to break or fling them against ... Mortar and pestle grinding can be accomplished with either manual or automated systems. ... Schematic representation of the crushing mechanism in a ball mill In wet grinding, the surrounding medium is liquid, as opposed to dry grinding.

LABORATORY AND PILOT SIZE MATERIALS TESTING AND .

IMPACT CRUSHER/HAMMERMILL Cast ductile iron, open latch ... and spheres, High Carbon Steel, Zirconia available for milling and grinding. SEPOR BATCH BALL MILL Constructed 316 stainless steel ... FRITSCH PULVERISETTE II Motorized mortar and pestle used for micromilling. Free turning pestle, flexible scraper, and sealed grinding ...

IMPACT CRUSHER/HAMMERMILL Cast ductile iron, open latch ... and spheres, High Carbon Steel, Zirconia available for milling and grinding. SEPOR BATCH BALL MILL Constructed 316 stainless steel ... FRITSCH PULVERISETTE II Motorized mortar and pestle used for micromilling. Free turning pestle, flexible scraper, and sealed grinding ...

6 reasons for the poor grinding effect of carbon black ...

Carbon black ball mill is a commonly used mine milling equipment. Due to some special reasons, it may cause coarse discharge, large particle size, unevenness, etc., which affect the quality and price of the finished product. The main reasons for the poor effect of carbon black ball mill eye mask are as follows.

Carbon black ball mill is a commonly used mine milling equipment. Due to some special reasons, it may cause coarse discharge, large particle size, unevenness, etc., which affect the quality and price of the finished product. The main reasons for the poor effect of carbon black ball mill eye mask are as follows.

Effect of ball load and size distribution on grinding and ...

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classifiion performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit. Mass balance of the circuit was done by JKSimMet Steady .

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classifiion performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit. Mass balance of the circuit was done by JKSimMet Steady .

الوظائف ذات الصلة

- كيفية بناء الفك صغير محطم

- كسارة مخروطية سلسلة cs تستخدم في التكسير

- آلات تصنيع الرمل للبيع في ناميبيا

- طحن وسحق الحجارة شركات مصر

- سكرتير مصنع كسارة

- تستخدم موبيل المعدات الرمال المحجر

- بيع كسارة متنقلة مدمجة

- معدات مصنع سحق كاراتشي

- معدات المحجر تاجر في المملكة العربية السعودية

- تجميع سحق النبات للبيع

- quarry sand washing machine cost for sale in south africa

- rock crushers inch cone

- lightweight concrete crusher

- forged grinding millsforging grinding balls

- process of manufacturing ordinary portland cement

- gypsum cone rock crusher in malaysia

- grinding machines d

- santha tilting grinder price in india

- durable hot selling stone jaw crusher machinery for limestone

- kumba iron ore mine learnerships for

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher