how to grind manganese ore fines particle

East Manganese on course to commence production in July 2021

May 24, 2021 · The ore will be processed using a dry crushing and screening plant system, which will reduce water usage at the plant, to produce lumpy and fine particle manganese products. Products will include both lumpy (85%) and fine material (15%). The plant is currently in the process of being commissioned.

May 24, 2021 · The ore will be processed using a dry crushing and screening plant system, which will reduce water usage at the plant, to produce lumpy and fine particle manganese products. Products will include both lumpy (85%) and fine material (15%). The plant is currently in the process of being commissioned.

Usage Of Manganese Ore

Usage Of Manganese Ore . The Magic of Manganese Dioxide What It Is and Why You . Mar 03 2013 The Magic of Manganese Dioxide What It Is and Why You Should Care March 3 2013 by wcpgu By Matthew Wirth The use of manganese dioxide goes back 17 000 years to the upper Paleolithic period when Stone Age men used it as a pigment for their cave paintings The Egyptians and the Romans used manganese ore .

Usage Of Manganese Ore . The Magic of Manganese Dioxide What It Is and Why You . Mar 03 2013 The Magic of Manganese Dioxide What It Is and Why You Should Care March 3 2013 by wcpgu By Matthew Wirth The use of manganese dioxide goes back 17 000 years to the upper Paleolithic period when Stone Age men used it as a pigment for their cave paintings The Egyptians and the Romans used manganese ore .

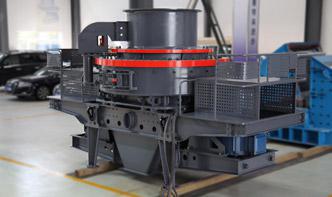

Vertical wet stirring mill_Ultra fine mill|Ultra fine ...

Jul 22, 2021 · Vertical wet stirring mill equipment is mainly divided into mixing mill (tower mill) and sand mill. The barrel of the stirring mill is thicker and the spindle angular velocity is lower. The grinding medium can be either a sphere or cylinder with a diameter of 412mm, or a microbead with a diameter of The angular speed of the main shaft of the sand mill is relatively high, .

Jul 22, 2021 · Vertical wet stirring mill equipment is mainly divided into mixing mill (tower mill) and sand mill. The barrel of the stirring mill is thicker and the spindle angular velocity is lower. The grinding medium can be either a sphere or cylinder with a diameter of 412mm, or a microbead with a diameter of The angular speed of the main shaft of the sand mill is relatively high, .

ia manganese ore concentrate machine for sale in ireland

ia manganese ore concentrate machine for sale in ireland. The buyer would like to receive quotations for Product Name Tungsten Powder Specifiions Purity % Artical,, Color Grey Quantity Required 1 TwentyFoot Container Shipping Terms FOB Or CIF Destination Port Busan, South Korea (Republic Of Korea) Payment Terms To be .

ia manganese ore concentrate machine for sale in ireland. The buyer would like to receive quotations for Product Name Tungsten Powder Specifiions Purity % Artical,, Color Grey Quantity Required 1 TwentyFoot Container Shipping Terms FOB Or CIF Destination Port Busan, South Korea (Republic Of Korea) Payment Terms To be .

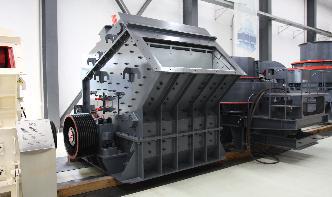

Manganese ore beneficiation production line,gravity ...

The manganese ore beneficiation production line is a system formed by a combination of equipments to improve the grade of manganese ore. It has the advantages of energy saving, high efficiency, environmental protection, and high degree of automation. The system has a good beneficiation effect on the beneficiation of manganese oxide and manganese carbonate.

The manganese ore beneficiation production line is a system formed by a combination of equipments to improve the grade of manganese ore. It has the advantages of energy saving, high efficiency, environmental protection, and high degree of automation. The system has a good beneficiation effect on the beneficiation of manganese oxide and manganese carbonate.

Grid Type Ball Mill VS Overflow Type Ball Mill, How to ...

May 18, 2020 · It can be used in the onestage grinding or twostage grinding to obtain the fine qualified products. As for the appliion range, the grid type ball mill is better if the material needs to be ground to the uniform coarse product (4865 mesh). The overflow mill is better if the material needs to be ground to the fine products (150200 mesh). 2.

May 18, 2020 · It can be used in the onestage grinding or twostage grinding to obtain the fine qualified products. As for the appliion range, the grid type ball mill is better if the material needs to be ground to the uniform coarse product (4865 mesh). The overflow mill is better if the material needs to be ground to the fine products (150200 mesh). 2.

Manganese

This reduces all of the manganese ore to manganese oxide (MnO), which is a leachable form. The ore then travels through a grinding circuit to reduce the particle size of the ore to between 150 and 250 μm, increasing the surface area to aid leaching. The ore is then added to a leach tank of sulfuric acid and ferrous iron (Fe 2+) in a :1 ratio.

This reduces all of the manganese ore to manganese oxide (MnO), which is a leachable form. The ore then travels through a grinding circuit to reduce the particle size of the ore to between 150 and 250 μm, increasing the surface area to aid leaching. The ore is then added to a leach tank of sulfuric acid and ferrous iron (Fe 2+) in a :1 ratio.

wany to grind mangnese

Wany To Grind Mangnese. mesh manganese grinding mills in papua new guinea,hammer mill grinding in papua new guinea. hammer mill grinding in papua new guinea apr 09 in the blog particle size reduction we touched based on the various types of equipment used to pregrind materials before extrusion the majority of projects we work on involve soybean .

Wany To Grind Mangnese. mesh manganese grinding mills in papua new guinea,hammer mill grinding in papua new guinea. hammer mill grinding in papua new guinea apr 09 in the blog particle size reduction we touched based on the various types of equipment used to pregrind materials before extrusion the majority of projects we work on involve soybean .

manganese ore separating jig 」

Manganese Ore Processing Technology and EquipmentJXSC . At present, gravity separation is only used to separate manganese ore with simple structure and coarse particle size, especially for manganese oxide ore with high manganese processing plant as an example, it mainly deals with leaching type manganese oxide ore, using AM30 jig machine treat 30 ~ 3 mm cleaning ore.

Manganese Ore Processing Technology and EquipmentJXSC . At present, gravity separation is only used to separate manganese ore with simple structure and coarse particle size, especially for manganese oxide ore with high manganese processing plant as an example, it mainly deals with leaching type manganese oxide ore, using AM30 jig machine treat 30 ~ 3 mm cleaning ore.

How much does it cost to invest in a Raymond mill ...

Clirik's Raymond mill is a new generation of traditional Raymond mill. The materials that can be ground are titanium dioxide, marble, feldspar, barite, ilmenite, phosphate rock, clay, clay, kaolin, Greenstone, wollastonite, slaked lime, bentonite, manganese ore, etc., these nonmetallic minerals with Mohs hardness below 7 and humidity within 6%, use Raymond mill to improve the .

Clirik's Raymond mill is a new generation of traditional Raymond mill. The materials that can be ground are titanium dioxide, marble, feldspar, barite, ilmenite, phosphate rock, clay, clay, kaolin, Greenstone, wollastonite, slaked lime, bentonite, manganese ore, etc., these nonmetallic minerals with Mohs hardness below 7 and humidity within 6%, use Raymond mill to improve the .

AIS Resources ships 200t manganese ore from San Jorge mine ...

AIS Resources has announced the initial trial shipment of highgrade fines manganese ore to China from a mine in San Jorge, Argentina. More than 200 tonnes of manganese ore was shipped on 66,380t container vessel, Tian Chang He. The company noted that there were no inspection delays on the first shipment and the voyage to Shanghai, China, is ...

AIS Resources has announced the initial trial shipment of highgrade fines manganese ore to China from a mine in San Jorge, Argentina. More than 200 tonnes of manganese ore was shipped on 66,380t container vessel, Tian Chang He. The company noted that there were no inspection delays on the first shipment and the voyage to Shanghai, China, is ...

Manganese carbonate ore beneficiation process

Manganese ore dressing have in common with other metal ore dressing, but also has its particularity. Because of China's manganese ore grade is low, high impurity, ore structure complex, fine particle size distribution, low grade manganese ore by the realization of "rich" is China's manganese industry technology policy need to insist for a long ...

Manganese ore dressing have in common with other metal ore dressing, but also has its particularity. Because of China's manganese ore grade is low, high impurity, ore structure complex, fine particle size distribution, low grade manganese ore by the realization of "rich" is China's manganese industry technology policy need to insist for a long ...

Magnetic Separation Process

Strong magnetic iron ore separation process. It is used to low grade magnetite. Due to the strong magnetic and easy to grind, one stage grinding is adopted for magnetite with coarse particle distribution, conversely the multi stages grinding. At present the fine grinding technology promoted by Xinhai improves the concentrate grate from 61% to 67%.

Strong magnetic iron ore separation process. It is used to low grade magnetite. Due to the strong magnetic and easy to grind, one stage grinding is adopted for magnetite with coarse particle distribution, conversely the multi stages grinding. At present the fine grinding technology promoted by Xinhai improves the concentrate grate from 61% to 67%.

China High Efficiency Mining Concentrator Gold Separator ...

Grinding equipment for wet fine grinding of ore (150 × 50 Cone Ball Mill also can be used for dry grinding). It is applied in labs for processing and fine grinding of artificial placer materials and ores in metallurgical, building material, chemical, light, coal, water conservancy, electric power, agricultural and geological industries. 3).

Grinding equipment for wet fine grinding of ore (150 × 50 Cone Ball Mill also can be used for dry grinding). It is applied in labs for processing and fine grinding of artificial placer materials and ores in metallurgical, building material, chemical, light, coal, water conservancy, electric power, agricultural and geological industries. 3).

Seven Tips Increasing Ball Mill Grinding Efficiency

Oct 26, 2020 · crushing and less grinding, reducing the feeding particle size of ball mill. The larger feeding particle size is, the greater the work done by the ball mill on the ore, which impacts the grinding efficiency. To reach the eligible grinding fineness, the workload must increase. The energy consumption is also increasing.

Oct 26, 2020 · crushing and less grinding, reducing the feeding particle size of ball mill. The larger feeding particle size is, the greater the work done by the ball mill on the ore, which impacts the grinding efficiency. To reach the eligible grinding fineness, the workload must increase. The energy consumption is also increasing.

Equipment Sizing: Crusher or Grinding Mill

Jul 08, 2016 · The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill feet in diameter in open circuit; and to a wet grinding overflow type ball mill feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 mesh.

Jul 08, 2016 · The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill feet in diameter in open circuit; and to a wet grinding overflow type ball mill feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 mesh.

Effect of Microwave Pretreatment on Grindability of Lead ...

Jul 16, 2021 · The influence of microwave pretreatment on grindability of leadzinc ore was studied through comparison analysis on the changes of particle size distribution, percentage of below mm, energy consumption, and other indexes of grinding products before and after microwave pretreatment in the ball milling process. The results showed that the grindability of leadzinc ore .

Jul 16, 2021 · The influence of microwave pretreatment on grindability of leadzinc ore was studied through comparison analysis on the changes of particle size distribution, percentage of below mm, energy consumption, and other indexes of grinding products before and after microwave pretreatment in the ball milling process. The results showed that the grindability of leadzinc ore .

Concentration process of Manganese ore_MECRU

1. The ore dressing program has the advantages of energy saving, high efficiency, environmental protection, and high degree of automation. It is suitable for large and mediumsized manganese ore beneficiation plants and has good beneficiation indiors for manganese oxide and manganese carbonate ore beneficiation.

1. The ore dressing program has the advantages of energy saving, high efficiency, environmental protection, and high degree of automation. It is suitable for large and mediumsized manganese ore beneficiation plants and has good beneficiation indiors for manganese oxide and manganese carbonate ore beneficiation.

Problems related to processing of manganese ore fines ...

Sep 01, 2010 · Generation of fines considerably depends on the nature of the ore, mining operations and handling systems. Particularly in Ukwa and Balaghat mines, the nature of ore is friable and generation of fines is considerable and is to the tune of 14% and 12% respectively. The percentage of manganese varies from 3035% in the fines.

Sep 01, 2010 · Generation of fines considerably depends on the nature of the ore, mining operations and handling systems. Particularly in Ukwa and Balaghat mines, the nature of ore is friable and generation of fines is considerable and is to the tune of 14% and 12% respectively. The percentage of manganese varies from 3035% in the fines.

Study of the Leaching of a Manganese Mining Residue by ...

Aug 30, 2013 · The IMINI manganese ore is characterized by the presence of a colloidal highly hydrated MnO2 gel, while crystalline phases include silie gangue minerals (albite, anorthite, quartz, etc.), though a few peaks are attributable to manganese dioxide minerals (pyrolusite, psilomelane and manganomelane [45].

Aug 30, 2013 · The IMINI manganese ore is characterized by the presence of a colloidal highly hydrated MnO2 gel, while crystalline phases include silie gangue minerals (albite, anorthite, quartz, etc.), though a few peaks are attributable to manganese dioxide minerals (pyrolusite, psilomelane and manganomelane [45].

الوظائف ذات الصلة

- الرسم ورقة تدفق من كسارة

- كسارة الفك والفرق محطم

- سعر مصنع تعدين الحجر الرملي

- الفرق الكروم والكروميت

- صناعة الطوب من كسارة الحجر غبار

- مطحنة طحن طلاء مصنوعة في السعودية

- بيع كسارة 150 طن

- الإيجار محطم في سعودي المملكة العربية

- خام الحديد معدات تجهيز الصين

- إنتاج المطاحن والكسارات في المملكة العربية السعودية

- opacity limits for por le rock crushers

- jaw crusher pdf drawings

- replacable parts for mining crushers

- milling lling crushing of antimony

- composite cone crusher office

- gold screening equipment

- powerpoint on concrete and cement ks science

- used parker mobile jaw crusher

- pre o do britador de movel de tonelada por horas novo

- kapan laki xcom crusher html

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher