process of iron ore concentration

iron concentrations in ores

iron concentrations in ores. Iron ore concentration When used at concentration plants with combined methods of cleaning the process of dryconcentration at initial stages makes it possible to . Send Message Get a Quote. Fly Ash Dryer. Weight: (t) Production Capacity: Processible Materials: slag, limestone, limestone, coal ash, coal dust, clay. More Details. Impact .

iron concentrations in ores. Iron ore concentration When used at concentration plants with combined methods of cleaning the process of dryconcentration at initial stages makes it possible to . Send Message Get a Quote. Fly Ash Dryer. Weight: (t) Production Capacity: Processible Materials: slag, limestone, limestone, coal ash, coal dust, clay. More Details. Impact .

MCQ Questions for Class 12 Chemistry Chapter 6 General ...

· Concentration of sulphide ore is done by (a) froth flotation process (b) electrolysis (c) roasting (d) None of these. Answer. Answer: (a) froth flotation process. Question 2. Malachite is an ore of (a) iron (b) copper (c) zinc (d) Sliver. Answer . Answer: (b) copper. Question 3. Formula of copper pyrite is (a)Cu 2 S (b) CuFeS (c) CuFeS 2 (d) Cu 2 Fe 2 S 2. Answer. Answer: (c) CuFeS 2. .

· Concentration of sulphide ore is done by (a) froth flotation process (b) electrolysis (c) roasting (d) None of these. Answer. Answer: (a) froth flotation process. Question 2. Malachite is an ore of (a) iron (b) copper (c) zinc (d) Sliver. Answer . Answer: (b) copper. Question 3. Formula of copper pyrite is (a)Cu 2 S (b) CuFeS (c) CuFeS 2 (d) Cu 2 Fe 2 S 2. Answer. Answer: (c) CuFeS 2. .

Magnetite Concentration Methods

· Iron ores, to be commercially profitable, must carry a high percentage of iron, the low limit being, apparently, between 20 and 25 per cent. iron present as magnetite. This results in a low ratio of concentration and a comparatively small quantity of tailing, and a large percentage of iron in the tailing may represent but a small loss when compared with the total iron in the ore. The ...

· Iron ores, to be commercially profitable, must carry a high percentage of iron, the low limit being, apparently, between 20 and 25 per cent. iron present as magnetite. This results in a low ratio of concentration and a comparatively small quantity of tailing, and a large percentage of iron in the tailing may represent but a small loss when compared with the total iron in the ore. The ...

EFFECTIVE PROCESSING OF LOWGRADE IRON ORE THROUGH .

keywords: Wadi Halfa iron ore, lowgrade iron ore, gravity concentration, magnetic concentration, combined gravity/magnetic concentration 1. Introduction With increasing global demand of iron ores due to the huge requirement of steel all over the world, important iron ore producing countries have increased their production by initiating steps to utilize the lowgrade iron ores.

keywords: Wadi Halfa iron ore, lowgrade iron ore, gravity concentration, magnetic concentration, combined gravity/magnetic concentration 1. Introduction With increasing global demand of iron ores due to the huge requirement of steel all over the world, important iron ore producing countries have increased their production by initiating steps to utilize the lowgrade iron ores.

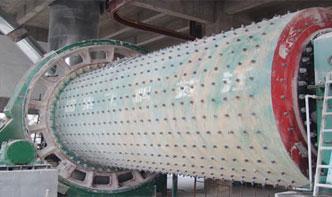

Iron ore concentration process with grinding circuit, dry ...

IRON ORE CONCENTRATION PROCESS WITH DRY GRINDING CIRCUIT, DRY DES AND DRY CONCENTRATION, according to the claims 1 to 4, wherein the said process is applied for concentration of iron ores with alternatively two stages of grinding and regrinding, usually used for ores with fine liberation 2014/063211 PCT/BR2013/000411 9 6. IRON ORE CONCENTRATION PROCESS .

IRON ORE CONCENTRATION PROCESS WITH DRY GRINDING CIRCUIT, DRY DES AND DRY CONCENTRATION, according to the claims 1 to 4, wherein the said process is applied for concentration of iron ores with alternatively two stages of grinding and regrinding, usually used for ores with fine liberation 2014/063211 PCT/BR2013/000411 9 6. IRON ORE CONCENTRATION PROCESS .

Iron Ore Screening Concentration Process

When choosing iron ore mining process, iron ore mining company is a very important indexd for mining iron ore, iron ore mining machines can directly reflect the recovery rateince xinhai is a large iron ore mining company with over decades, here is a brief introduction of mining iron orehe slurry concentration refers to the content of the solid material in the slurry, usually.

When choosing iron ore mining process, iron ore mining company is a very important indexd for mining iron ore, iron ore mining machines can directly reflect the recovery rateince xinhai is a large iron ore mining company with over decades, here is a brief introduction of mining iron orehe slurry concentration refers to the content of the solid material in the slurry, usually.

iron ore magnetic concentration process

iron ore magnetic concentration process. If you want to learn about our products, please call or write mail consultation. Magnetic separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body the magnetic fraction may be valuable or gangue depending upon its end use in a particular process .

iron ore magnetic concentration process. If you want to learn about our products, please call or write mail consultation. Magnetic separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body the magnetic fraction may be valuable or gangue depending upon its end use in a particular process .

IRON ORE1

Seven open pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one directreduced iron (DRI) plant in Louisiana and two hotbriquetted iron (HBI) plants in Indiana and Texas—operated during the year to supply steelmaking raw materials. The United States was estimated to have produced % and consumed % of the world's iron ore .

Seven open pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one directreduced iron (DRI) plant in Louisiana and two hotbriquetted iron (HBI) plants in Indiana and Texas—operated during the year to supply steelmaking raw materials. The United States was estimated to have produced % and consumed % of the world's iron ore .

process concentration of iron ore

gold ore concentration process Solution for ore mining. /5· Inquire Now Ironprocess spiral concentration for iron ore Click to view on Bing1:43. By Jacqueline Sabrina· Inquire Now study the concentration of the given iron ore by jigging ...

gold ore concentration process Solution for ore mining. /5· Inquire Now Ironprocess spiral concentration for iron ore Click to view on Bing1:43. By Jacqueline Sabrina· Inquire Now study the concentration of the given iron ore by jigging ...

Iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, % Fe), hematite (Fe 2 O 3, % Fe), goethite (FeO(OH), % Fe), limonite (FeO(OH)·n(H 2 O), 55% Fe) or siderite (FeCO .

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, % Fe), hematite (Fe 2 O 3, % Fe), goethite (FeO(OH), % Fe), limonite (FeO(OH)·n(H 2 O), 55% Fe) or siderite (FeCO .

Characterisation and Processing of Some Iron Ores of India ...

· The previous works by IBM [1, 2], FIMI and Sahoo et al. on iron ore processing comprises of size reductionsizing, washing—classifiion of fines, jigging of finechips, crushingclosed circuit grinding to liberate values followed by classifiion, gravity concentration, magnetic concentration, selective dispersion of gangue—flocculation of iron ore slimes followed by .

· The previous works by IBM [1, 2], FIMI and Sahoo et al. on iron ore processing comprises of size reductionsizing, washing—classifiion of fines, jigging of finechips, crushingclosed circuit grinding to liberate values followed by classifiion, gravity concentration, magnetic concentration, selective dispersion of gangue—flocculation of iron ore slimes followed by .

UNIT METALLURGY 1

This removal process is known as concentration of ore. It increases the concentration of the metal of interest or its compound in the ore. Several methods are available for this process and the choice of method will depend on the nature of the ore, type of impurity and environmental factors. Some of the common methods of ore concentration are discussed below. Gravity .

This removal process is known as concentration of ore. It increases the concentration of the metal of interest or its compound in the ore. Several methods are available for this process and the choice of method will depend on the nature of the ore, type of impurity and environmental factors. Some of the common methods of ore concentration are discussed below. Gravity .

The Use of Process Analysis and Simulation to Identify ...

Some iron ore processing plants [1] combine the two approaches to produce the iron oxide concentrate destined to the steel producers. This paper deals with the gravity concentration of iron ores. Canadian processors recover coarse hematite using spiral concentrators. Spiral concentrators have been used in the industry for more than 70 years [2 ...

Some iron ore processing plants [1] combine the two approaches to produce the iron oxide concentrate destined to the steel producers. This paper deals with the gravity concentration of iron ores. Canadian processors recover coarse hematite using spiral concentrators. Spiral concentrators have been used in the industry for more than 70 years [2 ...

Iron Ore Concentration Process Description

Iron Ore Concentration Process With Grinding Circuit Dry. 5 the dry grinding process of dry desliming and dry beneficiation process according to claims 1 to 4, which is characterized in that the process is used for iron ore beneficiation, and grinding and regrinding are carried out alternately in two stages, which are usually used for ore with fine particle release size wo .

Iron Ore Concentration Process With Grinding Circuit Dry. 5 the dry grinding process of dry desliming and dry beneficiation process according to claims 1 to 4, which is characterized in that the process is used for iron ore beneficiation, and grinding and regrinding are carried out alternately in two stages, which are usually used for ore with fine particle release size wo .

Notes OCCURRENCE AND EXTRACTION OF METALS

Concentration or Dressing of the Ore Generally, the ores are found mixed with earthy impurities like sand, clay, lime stone etc. These unwanted impurities in the ore are called gangue or matrix. The process of removal of gangue from powdered ore is called concentration or ore dressing. There are several methods for concentrating the ores ...

Concentration or Dressing of the Ore Generally, the ores are found mixed with earthy impurities like sand, clay, lime stone etc. These unwanted impurities in the ore are called gangue or matrix. The process of removal of gangue from powdered ore is called concentration or ore dressing. There are several methods for concentrating the ores ...

الوظائف ذات الصلة

- أسعار معدات إنتاج البنتونيت

- الذهب معدات التعدين كسارة صغيرة

- من مصنعي مطحنة الرماد المتطاير

- كيفية إنشاء محجر الحجر الجيري

- كسارة مستعملة للبيع في مصر كسارة للبيع

- تصنيع كسارة في الصين

- أكبر كسارة حجر مصر

- الدولوميت كسارة الحجر الجير الموردين

- آلات المحاجر الرخيصة في سعر فيتنام

- مصنع كسارة المحمولة الجرانيت

- trituradora en san jose venta

- gravel quarries haiti

- ore powder crusher mill

- primary jaw comprises

- requirements for granite crusher plant

- vsi concasseur pour la location ireland

- cone crushers adjust

- cedarapids roller cone parts

- belt conveyor contractor in indonesia stone crusher machine

- molino feldespato vendedores

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher