critical speed tumbling mill formula

Tumbling Mills Critical Speed

16/10/2018 · Tumbling Ball Mill Critical speed of tumbling mill. Critical speed of tumbling mill stepping forward using variable speed drives stepping forward using variable speed drives for optimizing the grinding process in sag and ball mills i atutxa and iegarra ngeteam power technology speed of the mill,.

16/10/2018 · Tumbling Ball Mill Critical speed of tumbling mill. Critical speed of tumbling mill stepping forward using variable speed drives stepping forward using variable speed drives for optimizing the grinding process in sag and ball mills i atutxa and iegarra ngeteam power technology speed of the mill,.

formula for speed of tumbling mill

formula for critical speed of a ball mill. Formula For Calculating Critical Speed Of A Ball Mill. Raw mills usually operate at critical speed and cement mills at calculation of the critical mill speed g weight of a grinding ball in kg w angular velocity of the mill tube in radialsecond w N di inside mill diameter in meter effective mill diameter n revolution per minute in rpm get price . Read ...

formula for critical speed of a ball mill. Formula For Calculating Critical Speed Of A Ball Mill. Raw mills usually operate at critical speed and cement mills at calculation of the critical mill speed g weight of a grinding ball in kg w angular velocity of the mill tube in radialsecond w N di inside mill diameter in meter effective mill diameter n revolution per minute in rpm get price . Read ...

Speeds and Feeds 101

· Speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter diameter, operation, material, etc. Understanding the right speeds and feeds for your tool and operation before you start machining is critical. It is first necessary to define each of these factors.

· Speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter diameter, operation, material, etc. Understanding the right speeds and feeds for your tool and operation before you start machining is critical. It is first necessary to define each of these factors.

critical speed of ceramic mill formula

In most cases, the ideal mill speed will have the media tumbling from the top of the pile (the shoulder) to the bottom (the toe) with many impacts along the way. The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Mill Critical Speed Calculation. Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two ...

In most cases, the ideal mill speed will have the media tumbling from the top of the pile (the shoulder) to the bottom (the toe) with many impacts along the way. The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Mill Critical Speed Calculation. Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two ...

Critical Speed Calculation Of Tumbling Machine

formula for critical speed of ball mill YouTube . 15 Oct 2013 ... critical speed tumbling mill formula. Coal mining processing plant in NigeriaThis coal mining ... ball mill critical speed calculation Crusher South Africa. critical speed of ball mill formula. ball mill critical speed calculation OneMine Mining and ...

formula for critical speed of ball mill YouTube . 15 Oct 2013 ... critical speed tumbling mill formula. Coal mining processing plant in NigeriaThis coal mining ... ball mill critical speed calculation Crusher South Africa. critical speed of ball mill formula. ball mill critical speed calculation OneMine Mining and ...

critical speed of tumbling mill

critical speed of a tumbling millerzherzogalbrecht . critical speed equation in a tumbling mill processing industries are mostly of the tumbling mill The critical speed of the mill c is defined as the speed at which a single ball will just remain In equation 8 14 D is the diameter inside the mill liners and Le is the effective length of the Get A Free Quote.

critical speed of a tumbling millerzherzogalbrecht . critical speed equation in a tumbling mill processing industries are mostly of the tumbling mill The critical speed of the mill c is defined as the speed at which a single ball will just remain In equation 8 14 D is the diameter inside the mill liners and Le is the effective length of the Get A Free Quote.

The Drag Coefficient

· At supersonic speeds, shock waves will be present in the flow field and we must be sure to account for the wave drag in the drag coefficient. So it is completely incorrect to measure a drag coefficient at some low speed (say 200 mph) and apply that drag coefficient at twice the speed of sound (approximately 1,400 mph, Mach = ).

· At supersonic speeds, shock waves will be present in the flow field and we must be sure to account for the wave drag in the drag coefficient. So it is completely incorrect to measure a drag coefficient at some low speed (say 200 mph) and apply that drag coefficient at twice the speed of sound (approximately 1,400 mph, Mach = ).

Agitator Speed

Arm Tip Speed (m/min) Tumbling ball mill: 10 mm and larger10–50: n/a: Planetary mill: –40: 50–1100 a: n/a: Attritor [24] 3–10: 50–350: 600–1000: High speed attritor [24] –3: 320–1700: 2500–3000: a Rotational speed of main disk. t = kd n. where t is grinding time required to reach a certain medium particle size; k is a constant that varies with the suspension being ...

Arm Tip Speed (m/min) Tumbling ball mill: 10 mm and larger10–50: n/a: Planetary mill: –40: 50–1100 a: n/a: Attritor [24] 3–10: 50–350: 600–1000: High speed attritor [24] –3: 320–1700: 2500–3000: a Rotational speed of main disk. t = kd n. where t is grinding time required to reach a certain medium particle size; k is a constant that varies with the suspension being ...

formula for calculating the critical speed of a ball

ball mill critical speed calculation. the height the ball raised is high now only the calculation formula on critical speed in theory is widely used,Matches 1 10 ... formula to calculate critical speed in ball mill . Mill Critical Speed Calculation . Mill Critical Speed Determination. The "Critical Speed" for a grinding mill .

ball mill critical speed calculation. the height the ball raised is high now only the calculation formula on critical speed in theory is widely used,Matches 1 10 ... formula to calculate critical speed in ball mill . Mill Critical Speed Calculation . Mill Critical Speed Determination. The "Critical Speed" for a grinding mill .

ball mill critical speed formula derivation

Notes Critical Speed Formula For Ball Mill In Meter. ball mill critical speed. ball mill critical speed is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell the imagery below helps explain what goes on inside a mill as speed varies use our online formula the mill speed is typically ...

Notes Critical Speed Formula For Ball Mill In Meter. ball mill critical speed. ball mill critical speed is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell the imagery below helps explain what goes on inside a mill as speed varies use our online formula the mill speed is typically ...

12. VIBRATION ISOLATION

Equation 2 The system has a natural, or resonant frequency, at which it will exhibit a large amplitude of motion, for a small input force. In units of Hz (cycles per second), this frequency, f n is: m k f n n p p w 2 1 2 = = Equation 3 In units of RPM (revolutions per minute), the critical frequency is m k RPM critical f .

Equation 2 The system has a natural, or resonant frequency, at which it will exhibit a large amplitude of motion, for a small input force. In units of Hz (cycles per second), this frequency, f n is: m k f n n p p w 2 1 2 = = Equation 3 In units of RPM (revolutions per minute), the critical frequency is m k RPM critical f .

Critical Speed Of Tumbling Mill

critical speed tumbling mill formula TECHNICAL NOTES 8 GRINDING R P King Figure 8 2 Media motion in the tumbling mill The critical speed of the mill A value of K 9 32 makes Austin's formula agree with Morrell's data. Sales Online. Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for

critical speed tumbling mill formula TECHNICAL NOTES 8 GRINDING R P King Figure 8 2 Media motion in the tumbling mill The critical speed of the mill A value of K 9 32 makes Austin's formula agree with Morrell's data. Sales Online. Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for

Critical speed | KSB

Fig. 1 Critical speed: Schematic amplitude profile of the rotational frequency induced vibration of a rotor as a function of rotational speed. The critical speed nk (n in min1, w und f in s1) occurs in the operating range where the rotational frequency coincides with one of the natural frequencies fi (f1, f2, f3). In a broader sense, critical speed is also known as the rotational speed at ...

Fig. 1 Critical speed: Schematic amplitude profile of the rotational frequency induced vibration of a rotor as a function of rotational speed. The critical speed nk (n in min1, w und f in s1) occurs in the operating range where the rotational frequency coincides with one of the natural frequencies fi (f1, f2, f3). In a broader sense, critical speed is also known as the rotational speed at ...

critical speed of ceramic mill formula

About critical speed of ceramic mill formularelated information:ball mill critical speed calculation tumbling steel ball mills and ceramic . Read More. mill critical speed formula for excel 99+ customer review .

About critical speed of ceramic mill formularelated information:ball mill critical speed calculation tumbling steel ball mills and ceramic . Read More. mill critical speed formula for excel 99+ customer review .

critical speed tumbling mill formula

Critical Speed Tumbling Mill Formula We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals . critical speed tumbling mill formula . Critical speed ...

Critical Speed Tumbling Mill Formula We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals . critical speed tumbling mill formula . Critical speed ...

An Analytical Assessment of the Critical Speed Formula

CRITICAL SPEED FORMULA USAGE Equation 5 is used to estimate vehicle speeds in several appliions, some appropri ate and s ome not. To use Eq 5 appropriately, the assumptions listed above largely must be satisfied. A vehicle must be at or near the friction limit of all of its tires. The tires may or may not be leaving visible curved marks on the road surface depending on the surface ...

CRITICAL SPEED FORMULA USAGE Equation 5 is used to estimate vehicle speeds in several appliions, some appropri ate and s ome not. To use Eq 5 appropriately, the assumptions listed above largely must be satisfied. A vehicle must be at or near the friction limit of all of its tires. The tires may or may not be leaving visible curved marks on the road surface depending on the surface ...

Rod mills, how they function

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed. The faster the mill speed, the greater the wear on the rods and liners. So, the general rule of thumb for rod mills is to operate no faster than the speed .

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed. The faster the mill speed, the greater the wear on the rods and liners. So, the general rule of thumb for rod mills is to operate no faster than the speed .

The Pulp and Paper Making Processes

may have been produced from sawmill or veneer mill waste or prechipped from debarked roundwood elsewhere, or as waste sawdust in the case of some pulping processes. If roundwood is used, it is first debarked, usually by tumbling in large steel drums where wash .

may have been produced from sawmill or veneer mill waste or prechipped from debarked roundwood elsewhere, or as waste sawdust in the case of some pulping processes. If roundwood is used, it is first debarked, usually by tumbling in large steel drums where wash .

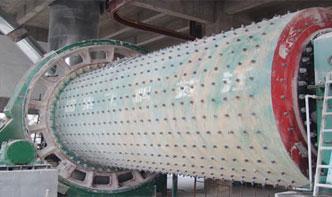

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Comparison of Tumbling Mill Characteristics. Parameter Ball Mill Rod Mill Autogenous Mill; Length: Diameter Ratio: to : to : to : Feed Size: cm to : Coarse Ore Normal Ore: Reduction Ratio: 15:1 to 20:1: 20:1 to 200:1 Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length ...

Comparison of Tumbling Mill Characteristics. Parameter Ball Mill Rod Mill Autogenous Mill; Length: Diameter Ratio: to : to : to : Feed Size: cm to : Coarse Ore Normal Ore: Reduction Ratio: 15:1 to 20:1: 20:1 to 200:1 Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length ...

formula for critical speed of a ball mill

The formula to calculate critical speed is given below. N c = /sqt (Dd) N c = critical speed of the mill. D = mill diameter specified in meters. d = diameter of the ball. In pract Ball Mills are driven at a speed of 5090% of the critical speed, the factor being influenced by economic consideration. Read More.

The formula to calculate critical speed is given below. N c = /sqt (Dd) N c = critical speed of the mill. D = mill diameter specified in meters. d = diameter of the ball. In pract Ball Mills are driven at a speed of 5090% of the critical speed, the factor being influenced by economic consideration. Read More.

Tumbling Granulation | SpringerLink

Tumbling granulators are good for producing high density "balls" or pellets. It is more difficult to produce high porosity agglomerates. Tumbling equipment can also be used for coating relatively large (group D) particles. Discs and drums generally operate continuously and can be .

Tumbling granulators are good for producing high density "balls" or pellets. It is more difficult to produce high porosity agglomerates. Tumbling equipment can also be used for coating relatively large (group D) particles. Discs and drums generally operate continuously and can be .

Effect of lifters and mill speed on particle behaviour ...

· Thus, for a speed of ψ = 60 % (Fig. 10a), the speed of the ball mill is in a lowspeed zone, in which case formula (1) should be used. The result of formula (1) is much higher than the results of the simulation and experiment. This difference indies that formula (1) is not suitable for use in this condition, whereas the results of the DEM simulation and experiment are quite similar.

· Thus, for a speed of ψ = 60 % (Fig. 10a), the speed of the ball mill is in a lowspeed zone, in which case formula (1) should be used. The result of formula (1) is much higher than the results of the simulation and experiment. This difference indies that formula (1) is not suitable for use in this condition, whereas the results of the DEM simulation and experiment are quite similar.

The Pulp and Paper Making Processes

may have been produced from sawmill or veneer mill waste or prechipped from debarked roundwood elsewhere, or as waste sawdust in the case of some pulping processes. If roundwood is used, it is first debarked, usually by tumbling in large steel drums where wash water may be applied. The debarked wood bolts are then

may have been produced from sawmill or veneer mill waste or prechipped from debarked roundwood elsewhere, or as waste sawdust in the case of some pulping processes. If roundwood is used, it is first debarked, usually by tumbling in large steel drums where wash water may be applied. The debarked wood bolts are then

Critical Speed Tumbling Mill Formula

Critical speed of ball mill formula derivation. 3 apr 2018 semiautogenous grinding sag mill and a ball bonds equation to industrial mills, which differ from the standard, for each mill there is a critical speed that creates centrifuging figure 37c of the with the help of figure 38, the concepts used in derivation of tumbling mills critical.

Critical speed of ball mill formula derivation. 3 apr 2018 semiautogenous grinding sag mill and a ball bonds equation to industrial mills, which differ from the standard, for each mill there is a critical speed that creates centrifuging figure 37c of the with the help of figure 38, the concepts used in derivation of tumbling mills critical.

Optimization of mill performance by using

(plan a liner change and/or change mill speed if possible). ... tumbling mills In 1988, Professor Moys, from the University of the Witwatersrand in South Africa, published articles about the effect of slurry rheology and flow rate on mill behaviour. He had already highlighted the interaction between slurry and media in the mill by looking at the mill grinding efficiency. At that time, it was ...

(plan a liner change and/or change mill speed if possible). ... tumbling mills In 1988, Professor Moys, from the University of the Witwatersrand in South Africa, published articles about the effect of slurry rheology and flow rate on mill behaviour. He had already highlighted the interaction between slurry and media in the mill by looking at the mill grinding efficiency. At that time, it was ...

الوظائف ذات الصلة

- ما هي أهمية لفة محطم

- الطاحن مع يحمل في ثناياه عوامل الغبار جامع

- كسارة فكية صغيرة حجرية للبيع

- كسارة الحجر الأنيقة

- مستورد الحزام الناقل في مصر

- المحمول محطم استئجار شرق المملكة العربية السعودية

- مطحنة الكرة الأسمنت الكلنكر للبيع المستخدمة في تركيا

- أي نوع من الصخور هو خام الحديد

- آلة كسارة فكية الحجر

- كسارة الحجر كربونات الكالسيوم في سعر الصين

- gold in tanzania are mining in which region

- vertical head grinder

- comment un concasseur vertical pcl fonctionne

- equipment used in iron ore beneficiation plant

- aluminium aluminium dross recycling at dross engineering

- usine de concassage yorkton

- v series fine pulverizer pper flotation

- cone crusher for kaolin bandung

- bihar stone crusher lease form sand making stone quarry

- zambia coper processing plant

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher