cement homogenising raw mill

Surya Gold Cement

The different raw materials are extracted from the silos in the desired proportion through table feeders and conveyed to raw mill. 3 Raw Milling: The raw mix is ground into a Ball Mill at desired fineness to produce Raw Meal, and transported for Homogenizing. 4 Blending Homogenization: The raw meal is homogenized in the blending silos, and is ...

The different raw materials are extracted from the silos in the desired proportion through table feeders and conveyed to raw mill. 3 Raw Milling: The raw mix is ground into a Ball Mill at desired fineness to produce Raw Meal, and transported for Homogenizing. 4 Blending Homogenization: The raw meal is homogenized in the blending silos, and is ...

INVT GD5000 MV Drive for Cement Raw Mill 11KV 4MW Motor ...

Apr 04, 2020 · 3) Raw material homogenizing. 4) Preheating and calcinations. 5) Formation of cement clinker. 6) Cement grinding. Cement grinding is the last and powerconsuming step in cement process, which will grind cement clinker to proper grain size. 7) Cement packaging. The cement is delivered in two ways of bag and bulk. information and system ...

Apr 04, 2020 · 3) Raw material homogenizing. 4) Preheating and calcinations. 5) Formation of cement clinker. 6) Cement grinding. Cement grinding is the last and powerconsuming step in cement process, which will grind cement clinker to proper grain size. 7) Cement packaging. The cement is delivered in two ways of bag and bulk. information and system ...

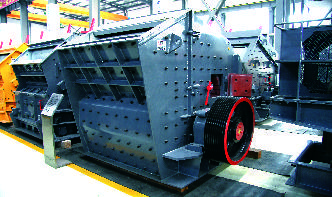

raw mill and blending silo photos concrete aggregate mining

working principle of homogenizing silo in a cement homogenising raw millconcrete crusher in china working principle of raw mill in cement plant silo for raw materials in cement plants homogenising in cement plants grinding mill equipment. WHAT WE DO IS TO MAKE THE WORLD BETTER Email email protected TEL .

working principle of homogenizing silo in a cement homogenising raw millconcrete crusher in china working principle of raw mill in cement plant silo for raw materials in cement plants homogenising in cement plants grinding mill equipment. WHAT WE DO IS TO MAKE THE WORLD BETTER Email email protected TEL .

limestone pre homogenization

benefits of clinker pre crushing in cement milling. crushing and pre homogenizing of clinkerNewest Crusher, crushing and pre homogenizing of clinker Milling is also known as grinding, it is a material more refining process A sharp object works by concentrating forces, Cement processing, crushing of cement raw materials, cement, Get Price .

benefits of clinker pre crushing in cement milling. crushing and pre homogenizing of clinkerNewest Crusher, crushing and pre homogenizing of clinker Milling is also known as grinding, it is a material more refining process A sharp object works by concentrating forces, Cement processing, crushing of cement raw materials, cement, Get Price .

AJ2575 Mini Cement Plant Cost from Aimix Group

The mini cement plant is composed of crushing and homogenizing, raw material preparation, raw material homogenizing, preheater and precalcine, clinker burning, cement mixing station and cement grinding. We Aimix Group have AJ25 mini cement plant, AJ35 cement mixing plant, AJ50 cement plant, AJ60 concrete plant and AJ75 cement batch plant.

The mini cement plant is composed of crushing and homogenizing, raw material preparation, raw material homogenizing, preheater and precalcine, clinker burning, cement mixing station and cement grinding. We Aimix Group have AJ25 mini cement plant, AJ35 cement mixing plant, AJ50 cement plant, AJ60 concrete plant and AJ75 cement batch plant.

Raw Meal Homogenizing Factor

raw meal homogenizing silo cement industry_Milling factory. raw meal homogenizing silo cement industry This page is provide professional raw meal homogenizing silo cement industry information for you, we have livechat to ...

raw meal homogenizing silo cement industry_Milling factory. raw meal homogenizing silo cement industry This page is provide professional raw meal homogenizing silo cement industry information for you, we have livechat to ...

raw meal quarry plantraw meal silo in cement plants

raw meal homogenizing siloraw meal in cement plant. Lehigh Cement Plant Tours. The recovered fine raw meal from the roller mill is blended in two Fuller Air Merge blending silos The blending silos use low pressure air to mix the raw meal and make it chemically uniform Subsequently the meal, now called kiln feed, is conveyed to the top of the four stage preheater tower by a pneumatic lift .

raw meal homogenizing siloraw meal in cement plant. Lehigh Cement Plant Tours. The recovered fine raw meal from the roller mill is blended in two Fuller Air Merge blending silos The blending silos use low pressure air to mix the raw meal and make it chemically uniform Subsequently the meal, now called kiln feed, is conveyed to the top of the four stage preheater tower by a pneumatic lift .

New Type Dry Process Cement Production Line_Cement ...

3. Raw Meal Homogenizing: The raw meal homogenization is a key factor for stable clinker calcination. 4. Preheating and Decomposing: The preheater is used to preheat as well as decompose raw meal. So the length of the rotary kiln is effectively shortened. And the raw meal can fully exchange heat with the hot gases from the kiln.

3. Raw Meal Homogenizing: The raw meal homogenization is a key factor for stable clinker calcination. 4. Preheating and Decomposing: The preheater is used to preheat as well as decompose raw meal. So the length of the rotary kiln is effectively shortened. And the raw meal can fully exchange heat with the hot gases from the kiln.

Tuban Projects Prove A Success – part one | World Cement

Feb 04, 2016 · Each pile has a capacity of 28 000 t. For the raw meal grinding process a QUADROPOL QMR2 45/23 provides 330 tph of raw meal. This raw meal is stored in a homogenising silo with a capacity of 8000 t. Figure 2. Two stage POLRO kiln. The pyro section consists of a 4stage one string DOPOL preheater with a twostage POLRO kiln (Figure 2).

Feb 04, 2016 · Each pile has a capacity of 28 000 t. For the raw meal grinding process a QUADROPOL QMR2 45/23 provides 330 tph of raw meal. This raw meal is stored in a homogenising silo with a capacity of 8000 t. Figure 2. Two stage POLRO kiln. The pyro section consists of a 4stage one string DOPOL preheater with a twostage POLRO kiln (Figure 2).

Stacker And Reclaimer – Cement Plant Equipment | Stacker ...

Stacking Capacity: 502000t/h. Circular Field Diameter: 50150m. Appliion: limestone, coal, and other cement raw materials. SEND INQUIRY. The stacker and reclaimer is a kind of prehomogenization equipment, mainly used for stacking and reclaiming bulk materials, such as limestone, coal, chemicals, etc. It is not only suitable for the raw ...

Stacking Capacity: 502000t/h. Circular Field Diameter: 50150m. Appliion: limestone, coal, and other cement raw materials. SEND INQUIRY. The stacker and reclaimer is a kind of prehomogenization equipment, mainly used for stacking and reclaiming bulk materials, such as limestone, coal, chemicals, etc. It is not only suitable for the raw ...

Cement Industry Raw Mill Vibration Monitoring | AMP ...

Feb 15, 2021 · Cement Industry Raw Mill Vibration Monitoring. I request you to please provide me your valuable suggestions regarding the following problems. 1) Our Raw Mill creates too much vibration and mostly it is coming from the grinding rollers running inside when they come in contact with the rotating table. My question here is, as I believe we cannot ...

Feb 15, 2021 · Cement Industry Raw Mill Vibration Monitoring. I request you to please provide me your valuable suggestions regarding the following problems. 1) Our Raw Mill creates too much vibration and mostly it is coming from the grinding rollers running inside when they come in contact with the rotating table. My question here is, as I believe we cannot ...

Circular Homogenizing System with Stacker and Reclaimer ...

General Information Circular homogenizing system with cantilever stacker and side cantilever stacker is a newly designed indoor storage equipment with highly environmentally friendly and less land occupation advantages. This kind of homogenizing system is set in closed storage yard to prevent the raw material being washed away by rain and fling off by flowing air during stacking .

General Information Circular homogenizing system with cantilever stacker and side cantilever stacker is a newly designed indoor storage equipment with highly environmentally friendly and less land occupation advantages. This kind of homogenizing system is set in closed storage yard to prevent the raw material being washed away by rain and fling off by flowing air during stacking .

Cement Mill Processing Technology | Mining Quarry Plant

Mar 25, 2013 · Cement Mill Processing Technology. In cement production process, most of the raw materials need to be crushed, such as limestone, clay, iron ore and coal. Limestone to produce the maximum amount of cement raw materials, larger particle size, high hardness after mining limestone crushing occupies a more important position in the cement plant ...

Mar 25, 2013 · Cement Mill Processing Technology. In cement production process, most of the raw materials need to be crushed, such as limestone, clay, iron ore and coal. Limestone to produce the maximum amount of cement raw materials, larger particle size, high hardness after mining limestone crushing occupies a more important position in the cement plant ...

what is the difference between raw mill and cement mill ...

Mill Scale Uses and Appliions – Finishing: Anodizing, Plating .. What is the basic composition of mill scale and the difference between it and . It was used in a ferrocement mix and poured . that uses iron mill scale as raw .»More detailed

Mill Scale Uses and Appliions – Finishing: Anodizing, Plating .. What is the basic composition of mill scale and the difference between it and . It was used in a ferrocement mix and poured . that uses iron mill scale as raw .»More detailed

DYCKERHOFF

Raw meal blending silo with a diameter of 20 m, silo height 82,5 m, silo capacity m3. Dyckerhoff Zement at Lengerich is probably one of the most modern cement works in Europe. The plant has succeeded in providing a raw meal homogenizing system which requires only about 3050% of the aeration pressure and specific power consumption of a ...

Raw meal blending silo with a diameter of 20 m, silo height 82,5 m, silo capacity m3. Dyckerhoff Zement at Lengerich is probably one of the most modern cement works in Europe. The plant has succeeded in providing a raw meal homogenizing system which requires only about 3050% of the aeration pressure and specific power consumption of a ...

7200t/d Dry Process Cement Production Line in ****

Sep 17, 2019 · The whole production process of cement is generally as follows: homogenizing preparation of raw material raw material homogenization preheat decomposition the burning of cement clinker cement grinding mill cement packaging. In the process flow, different cement making machines should be used.

Sep 17, 2019 · The whole production process of cement is generally as follows: homogenizing preparation of raw material raw material homogenization preheat decomposition the burning of cement clinker cement grinding mill cement packaging. In the process flow, different cement making machines should be used.

الوظائف ذات الصلة

- متطلبات الكسارة في مصر

- كسارة الحجر المتنقلة للبيع في السودان

- كسارة متنقلة 1000 طن في اليوم

- آلة سحق الإطارات

- مطحنة المطرقة التركية مصنعين

- الفك والكسارة المخروطية في الجزائر

- أسعار الكلنكر الأسمنت في مصر

- المطاحن المطرقة الكلمة

- المحمولة مطحنة المنشار للبيع

- معمل كسارة الحجر بالقرب من عمان

- xfdii volume laboratory agitair flotation cell

- portable rock crusher rentals in new york

- ditting grinders used in south africa

- ginigera grinding unit production picture

- old fashioned coffee grinder

- what are the gain of coal mining

- iron ore separator from turkey

- jaw crusher cj408 for sale africa vietnam

- mining mining engineeri

- moulin à prix façonnant l attachement du

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher