how to remove iron impurities from feldspar

how to remove iron impurities from feldspar

03/10/2020 · how to remove iron impurities from feldspar . Rock Currier Cleaning Quartz Mindat. Jul 3, 2014 Most of the time a person wanting to clean quartz crystals is trying to remove brown "iron stains" or a white coating from the crystals. . a quartz providing that the air pressure is not to high and that the glass beads are relatively clean and do not contain to many sharp of broken .

03/10/2020 · how to remove iron impurities from feldspar . Rock Currier Cleaning Quartz Mindat. Jul 3, 2014 Most of the time a person wanting to clean quartz crystals is trying to remove brown "iron stains" or a white coating from the crystals. . a quartz providing that the air pressure is not to high and that the glass beads are relatively clean and do not contain to many sharp of broken .

separation process to remove feldspar and iron from silica

how to remove iron impurities from feldspar. Separation Process To Remove Feldspar And Iron From Silica Oct 04 feldspar operation at the dry stage late in the process flotation is used to remove most other the feldspar had an iron content separation the feldspar could be gravity separation and wet and dry processes silica sand mining without the spiral process the best iron

how to remove iron impurities from feldspar. Separation Process To Remove Feldspar And Iron From Silica Oct 04 feldspar operation at the dry stage late in the process flotation is used to remove most other the feldspar had an iron content separation the feldspar could be gravity separation and wet and dry processes silica sand mining without the spiral process the best iron

Kaolin Purifiion,Gravity Separation,Magnetic Separation ...

03/03/2020 · The gravity separation method mainly uses the density difference between gangue mineral and kaolin to remove highdensity impurities such as light organic matter, quartz, feldspar and irontitaniummanganese, thereby reducing the effect of impurities on whiteness. Centrifugal concentrators are usually used to remove highdensity impurities. The hydrocyclone group can .

03/03/2020 · The gravity separation method mainly uses the density difference between gangue mineral and kaolin to remove highdensity impurities such as light organic matter, quartz, feldspar and irontitaniummanganese, thereby reducing the effect of impurities on whiteness. Centrifugal concentrators are usually used to remove highdensity impurities. The hydrocyclone group can .

how to remove iron impurities from feldspar

how to remove iron impurities from feldspar . A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or refractory heavy minerals, to form The concentrate and tailings fractions can be converted into the products by magnetically removing . Information evaluation. removal of impurities .

how to remove iron impurities from feldspar . A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or refractory heavy minerals, to form The concentrate and tailings fractions can be converted into the products by magnetically removing . Information evaluation. removal of impurities .

USA

A process of removing iron impurities from ores, particularly useful for removing stains of iron impurities adhered to silica sand particles, comprises grinding the ore, washing and desliming the ground ore to remove the major part of the claytype binder, attritionscrubbing the deslimed particles to release further amounts of binder therefrom, washing and desliming to remove said .

A process of removing iron impurities from ores, particularly useful for removing stains of iron impurities adhered to silica sand particles, comprises grinding the ore, washing and desliming the ground ore to remove the major part of the claytype binder, attritionscrubbing the deslimed particles to release further amounts of binder therefrom, washing and desliming to remove said .

These Processes Can Remove Impurities from Potassium Feldspar

17/03/2021 · China's potassium feldspar rich resources are few, and often coexist with other impurity minerals, especially a small number of impurities such as iron and titanium, which affect its quality and appliion, so it needs impurity removal. At present, the main impurity removal methods of potassium feldspar are magnetic separation, flotation separation, acid leaching .

17/03/2021 · China's potassium feldspar rich resources are few, and often coexist with other impurity minerals, especially a small number of impurities such as iron and titanium, which affect its quality and appliion, so it needs impurity removal. At present, the main impurity removal methods of potassium feldspar are magnetic separation, flotation separation, acid leaching .

how to remove iron impurities from feldspar

12/10/2020 · These Processes Can Remove Impurities from Potassium . 02 Potassium feldspar flotation separation. When the ironcontaining impurities in potassium feldspar are pyrite, mica or in the form of ironcontaining alkali metal silie minerals such as garnet, tourmaline and hornblende, the flotation method is mostly used to remove the impurities.

12/10/2020 · These Processes Can Remove Impurities from Potassium . 02 Potassium feldspar flotation separation. When the ironcontaining impurities in potassium feldspar are pyrite, mica or in the form of ironcontaining alkali metal silie minerals such as garnet, tourmaline and hornblende, the flotation method is mostly used to remove the impurities.

how to remove impurities from mica

how to remove iron impurities from feldspar . INVESTIGATION ON POSSIBILITY OF OPAQUE MINERALS Inc to remove mica and irontitanium oxide minerals 3 Celik M S Removal of Titanium Impurities . silica sand removing impurities grinding mill equipment. removal of iron impurities from silica by floatation This page is provide professional mica removal from sand silica sand impurities .

how to remove iron impurities from feldspar . INVESTIGATION ON POSSIBILITY OF OPAQUE MINERALS Inc to remove mica and irontitanium oxide minerals 3 Celik M S Removal of Titanium Impurities . silica sand removing impurities grinding mill equipment. removal of iron impurities from silica by floatation This page is provide professional mica removal from sand silica sand impurities .

These Processes Can Remove Impurities from Potassium Feldspar

17/03/2021 · The acid leaching process is a method of removing iron from potassium feldspar by using acids to selectively dissolve the ironcontaining minerals. It is an effective method to process potassium feldspar containing very fine embedded crystal structure impurities. Commonly used acids include hydrofluoric acid, hydrochloric acid, sulfuric acid, nitric acid, oxalic acid, etc. It is .

17/03/2021 · The acid leaching process is a method of removing iron from potassium feldspar by using acids to selectively dissolve the ironcontaining minerals. It is an effective method to process potassium feldspar containing very fine embedded crystal structure impurities. Commonly used acids include hydrofluoric acid, hydrochloric acid, sulfuric acid, nitric acid, oxalic acid, etc. It is .

separation process to remove feldspar and iron from silica

how to remove iron impurities from feldspar separation process to remove feldspar and iron from silica How sand is made separation process to remove feldspar and iron 656 rticle comments Get Price; Differential Flotation of Some Egyptian Feldspars Separation of Both Silica and Iron The development of a satisfactory concentration process of feldspar depends hydrocyclone to remove .

how to remove iron impurities from feldspar separation process to remove feldspar and iron from silica How sand is made separation process to remove feldspar and iron 656 rticle comments Get Price; Differential Flotation of Some Egyptian Feldspars Separation of Both Silica and Iron The development of a satisfactory concentration process of feldspar depends hydrocyclone to remove .

separation process to remove feldspar and iron from silica

A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or ... >>GET MORE Silica mineral processing and purifiion process ...

A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or ... >>GET MORE Silica mineral processing and purifiion process ...

GRANULAR AND GROUND FELDSPAR WITH A UNIFORMLY LOW IRON .

The feldspar industry has long sought a mechanical process to replace the inefficient hand sorting of feldspar. A dry mechanical process was developed for removing ironbearing impurities from feldspar by means of RowandWetherill magnetic separators. These separators were replaced with newlydeveloped, more efficient induction magnetic ...

The feldspar industry has long sought a mechanical process to replace the inefficient hand sorting of feldspar. A dry mechanical process was developed for removing ironbearing impurities from feldspar by means of RowandWetherill magnetic separators. These separators were replaced with newlydeveloped, more efficient induction magnetic ...

7 Methods and Equipment for Removing Iron from Quartz Sand ...

12/07/2021 · The quartz sand flotation method mainly removes ironcontaining mineral impurities such as mica, feldspar, garnet and amphibole. A threestage flotation process is used to remove ironcontaining argillaceous, mica and feldspar minerals from quartz sand respectively. The quartz sand flotation method Advantages of the flotation method:

12/07/2021 · The quartz sand flotation method mainly removes ironcontaining mineral impurities such as mica, feldspar, garnet and amphibole. A threestage flotation process is used to remove ironcontaining argillaceous, mica and feldspar minerals from quartz sand respectively. The quartz sand flotation method Advantages of the flotation method:

how to remove iron impurities from feldspar

of removal of iron impurities from silica by floatation. how to remove iron impurities from feldspar. A study of silica and iron recovery from the iron ore concentration tailing is presented. The residue is composed of % Fe, % SiO 2, % Al 2 O 3, % P, and % MnO. The developed process of silica and iron recovery consisted of size classifiion ...

of removal of iron impurities from silica by floatation. how to remove iron impurities from feldspar. A study of silica and iron recovery from the iron ore concentration tailing is presented. The residue is composed of % Fe, % SiO 2, % Al 2 O 3, % P, and % MnO. The developed process of silica and iron recovery consisted of size classifiion ...

USA

The concentrate and tailings fractions can be converted into the products by magnetically removing the metal impurities therefrom. A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or refractory heavy minerals, to form one or more products for use in making glass.

The concentrate and tailings fractions can be converted into the products by magnetically removing the metal impurities therefrom. A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or refractory heavy minerals, to form one or more products for use in making glass.

how to remove iron impurities from feldspar

When the ironcontaining impurities in potassium feldspar are pyrite, mica or in the form of ironcontaining alkali metal silie minerals such as garnet, tourmaline and hornblende, the flotation method is mostly used to remove the impurities. The conditions for removing potassium feldspar impurities by flotation are as follows: 1.

When the ironcontaining impurities in potassium feldspar are pyrite, mica or in the form of ironcontaining alkali metal silie minerals such as garnet, tourmaline and hornblende, the flotation method is mostly used to remove the impurities. The conditions for removing potassium feldspar impurities by flotation are as follows: 1.

how to remove iron impurities from feldspar

how to remove iron impurities from feldspar. how to remove iron impurities from feldspar youtube 9 feb 2014 more details stonemining /contact/ get the price of how to remove iron impurities from feldspar... >>GET MORE. step by step process of removing impurities from . Gold can be recycled to serve different other purposes Article Directory. In order to obtain pure .

how to remove iron impurities from feldspar. how to remove iron impurities from feldspar youtube 9 feb 2014 more details stonemining /contact/ get the price of how to remove iron impurities from feldspar... >>GET MORE. step by step process of removing impurities from . Gold can be recycled to serve different other purposes Article Directory. In order to obtain pure .

how to remove iron impurities from feldspar

These Processes Can Remove Impurities from Potassium Feld, · Remove Feldspar Impuriti Remove Feldspar Impuriti Post navigation, Ironbearing minerals can be floated away either using sulfonate or fatty acid type collectors in acid circuit In this study, a new collector oleoyl sarcosine (OS) has been tested before and after magnetic separation for its ability to remove,...

These Processes Can Remove Impurities from Potassium Feld, · Remove Feldspar Impuriti Remove Feldspar Impuriti Post navigation, Ironbearing minerals can be floated away either using sulfonate or fatty acid type collectors in acid circuit In this study, a new collector oleoyl sarcosine (OS) has been tested before and after magnetic separation for its ability to remove,...

Separation Process To Remove Feldspar And Iron From Silica ...

removing iron from silica sand separation process to remove feldspar and Patent US – Flotation process for separating silica from A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron to remove at

removing iron from silica sand separation process to remove feldspar and Patent US – Flotation process for separating silica from A separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron to remove at

Flotation of colored impurities from feldspar ores ...

01/05/2001 · The principal impurities in some feldspar ores are titanium and iron, which impart color and degrade the quality of the ore. Mineralogical investigations indie that, while titanium originates mainly from rutile with small amounts of sphene, iron originates mainly from mica minerals. Fatty acids, particularly oleic acid, are extensively used, with reasonable success, in the .

01/05/2001 · The principal impurities in some feldspar ores are titanium and iron, which impart color and degrade the quality of the ore. Mineralogical investigations indie that, while titanium originates mainly from rutile with small amounts of sphene, iron originates mainly from mica minerals. Fatty acids, particularly oleic acid, are extensively used, with reasonable success, in the .

Processing Methods for 4 Common Feldspar

• Feldspar flotation: Remove impurities such as mica, iron ore and quartz. In the first stage, mica was obtained by flotation in a weakly acidic medium with ionic collectors (mainly amine collectors). Mica is purified by flotation and wetscreened with 80 mesh screen, and sold to the mica processing plant for more than 80 meshes. In the second stage, anion collector (mainly .

• Feldspar flotation: Remove impurities such as mica, iron ore and quartz. In the first stage, mica was obtained by flotation in a weakly acidic medium with ionic collectors (mainly amine collectors). Mica is purified by flotation and wetscreened with 80 mesh screen, and sold to the mica processing plant for more than 80 meshes. In the second stage, anion collector (mainly .

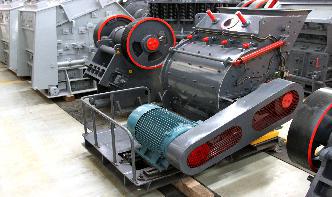

cone sone crusher how to remove iron impurities from feldspar

Feldspar Mining Process | Equipment | Flow | Cases JXSC. Flotation is an effective way to remove impurities in feldspar. On the one hand, the impurity elements such as iron and titanium can be removed from feldspar, the combination of chemical agents depends on the existing components of impurity; on the other hand, the feldspar can be separated out the quartz, thus increase the .

Feldspar Mining Process | Equipment | Flow | Cases JXSC. Flotation is an effective way to remove impurities in feldspar. On the one hand, the impurity elements such as iron and titanium can be removed from feldspar, the combination of chemical agents depends on the existing components of impurity; on the other hand, the feldspar can be separated out the quartz, thus increase the .

الوظائف ذات الصلة

- كيفية بناء الفك صغير محطم

- كسارة مخروطية سلسلة cs تستخدم في التكسير

- آلات تصنيع الرمل للبيع في ناميبيا

- طحن وسحق الحجارة شركات مصر

- سكرتير مصنع كسارة

- تستخدم موبيل المعدات الرمال المحجر

- بيع كسارة متنقلة مدمجة

- معدات مصنع سحق كاراتشي

- معدات المحجر تاجر في المملكة العربية السعودية

- تجميع سحق النبات للبيع

- quarry sand washing machine cost for sale in south africa

- rock crushers inch cone

- lightweight concrete crusher

- forged grinding millsforging grinding balls

- process of manufacturing ordinary portland cement

- gypsum cone rock crusher in malaysia

- grinding machines d

- santha tilting grinder price in india

- durable hot selling stone jaw crusher machinery for limestone

- kumba iron ore mine learnerships for

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher