iron ore mining separation process

Extraction of Nickel from Garnierite Laterite Ore Using ...

Furthermore, the segregation roasting ores will be difficult to grind and affect the recovery of nickel and iron in the magnetic separation process. Therefore, the roasting temperature of 1100 °C is suitable; a ferronickel concentrate with a nickel grade of %, iron content of %, and nickel recovery of % was obtained.

Furthermore, the segregation roasting ores will be difficult to grind and affect the recovery of nickel and iron in the magnetic separation process. Therefore, the roasting temperature of 1100 °C is suitable; a ferronickel concentrate with a nickel grade of %, iron content of %, and nickel recovery of % was obtained.

Dry processing of magnetic iron ores – addressing cost and ...

The Iron ore industry has reached the end of an unprecedented period of expansion triggered by China's demand for iron ore. Currently, lower ore prices have led producers to focus on optimizing mining operations while extracting the maximum tonnage from the infrastructure presently in place or from projects already underway.

The Iron ore industry has reached the end of an unprecedented period of expansion triggered by China's demand for iron ore. Currently, lower ore prices have led producers to focus on optimizing mining operations while extracting the maximum tonnage from the infrastructure presently in place or from projects already underway.

Iron Ore Mining Business Process SAP Solution | SAP Blogs

11/03/2009 · Iron Ore Mining – Business Process SAP Solution. 4 0 2,107. Iron Ore Mining is one of the major Industry of Karnataka State in India. Bellary District alone in Karnataka houses about 60 Mines and produces over 40 million Tons of Iron Ore per annum. China was a major customer and of the 40 Million Tonnes Iron Ore produced in Bellary, 30 ...

11/03/2009 · Iron Ore Mining – Business Process SAP Solution. 4 0 2,107. Iron Ore Mining is one of the major Industry of Karnataka State in India. Bellary District alone in Karnataka houses about 60 Mines and produces over 40 million Tons of Iron Ore per annum. China was a major customer and of the 40 Million Tonnes Iron Ore produced in Bellary, 30 ...

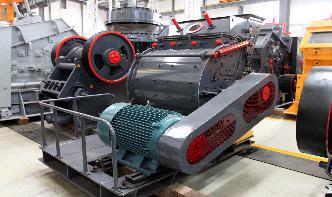

Iron ore mining process and iron ore mining equipments SBM

Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening. This is usually so efficient that lower grade ore can be treated especially when the magnetite is .

Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening. This is usually so efficient that lower grade ore can be treated especially when the magnetite is .

Iron Ore Analysis Process Optimization Solutions ...

Process integrators Filtration Granulation Homogenization Milling and grinding Oil and water separation Plant optimization Separation and classifiion; ... iron ore miners can define ore grade, ensure accurate mine planning and predict the upgradability of iron ore to save more than 1 million USD per grade block that is incorrectly classified ...

Process integrators Filtration Granulation Homogenization Milling and grinding Oil and water separation Plant optimization Separation and classifiion; ... iron ore miners can define ore grade, ensure accurate mine planning and predict the upgradability of iron ore to save more than 1 million USD per grade block that is incorrectly classified ...

SEPARATION EXPERTISE FOR YOUR SUCCESS IN THE MINING .

any separation challenge The mining and minerals industry demands unique capabilities ... iron ore, potash, coal, and more, every solution comes ... any separation process CENTRIFUGATION. 11 FILTRATION DRYING Heavy duty belt press Filter presses Drum filter

any separation challenge The mining and minerals industry demands unique capabilities ... iron ore, potash, coal, and more, every solution comes ... any separation process CENTRIFUGATION. 11 FILTRATION DRYING Heavy duty belt press Filter presses Drum filter

RESOUR CE PA CK Iron Mining and Processing in South Africa

transports the ore to the crushers at the processing plant. Blending and dispatch Blast furnace Washing and screening Surface mining Steel manufacturing Separation and classifiion Pig iron Slag Iron Ore (65% Fe) The ore undergoes a series of crushing steps to reduce the particle size. Iron ore is separated into the different grades using ...

transports the ore to the crushers at the processing plant. Blending and dispatch Blast furnace Washing and screening Surface mining Steel manufacturing Separation and classifiion Pig iron Slag Iron Ore (65% Fe) The ore undergoes a series of crushing steps to reduce the particle size. Iron ore is separated into the different grades using ...

Magnetic separation for mining industry – Magnetense

This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm ( – 200 mesh of 30100 %) of fine grained red mine (hematite) limonite, manganese ore, ilmenite and some kinds of weakly magnetic minerals like quartz, feldspar, nepheline ore and kaolin in order to remove impurity iron and to purify them.

This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm ( – 200 mesh of 30100 %) of fine grained red mine (hematite) limonite, manganese ore, ilmenite and some kinds of weakly magnetic minerals like quartz, feldspar, nepheline ore and kaolin in order to remove impurity iron and to purify them.

(PDF) Dry Magnetic Separation of Iron Ore of the Bakchar ...

[Show full abstract] results show that the separation process of high intensity magneticreverse flotation can obtain an iron concentrate grading about % at a recovery of % from an ...

[Show full abstract] results show that the separation process of high intensity magneticreverse flotation can obtain an iron concentrate grading about % at a recovery of % from an ...

Mining of Iron Ores – IspatGuru

14/03/2014 · Processing of the ore ranges from simple crushing and screening and separating various size fractions of the ore to the processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by difference in particle density or size gravity or size separation.

14/03/2014 · Processing of the ore ranges from simple crushing and screening and separating various size fractions of the ore to the processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by difference in particle density or size gravity or size separation.

Mining and metallurgy: The role of filters in ...

26/02/2010 · The market for filtration and related separation equipment (including spare parts) is expected to have been about billion in 2009, for the nonenergy mining and mineral sector, and this is expected to rise by about 30% by 2014. This market size represents a share of about % of the total global market, although the share will be somewhat ...

26/02/2010 · The market for filtration and related separation equipment (including spare parts) is expected to have been about billion in 2009, for the nonenergy mining and mineral sector, and this is expected to rise by about 30% by 2014. This market size represents a share of about % of the total global market, although the share will be somewhat ...

Tin ore separation process

The density of tin ore is bigger than paragenetic mineral, so we use gravity concentration to processing tin ore . Because there are many oxide iron ore inside, for example : magnetite, hematite, if use gravity concentration or flotation, that could not separate them from tin, so magnetic will be added .It is a high technological enterprise that integrated research, .

The density of tin ore is bigger than paragenetic mineral, so we use gravity concentration to processing tin ore . Because there are many oxide iron ore inside, for example : magnetite, hematite, if use gravity concentration or flotation, that could not separate them from tin, so magnetic will be added .It is a high technological enterprise that integrated research, .

SensorBased Ore Sorting Technology in Mining—Past ...

Sensorbased ore sorting can be used as a separation process for coarser grain sizes before the appliion of fine comminution and separation technologies and is applicable for a large variety of mineral raw materials. ... gold, copper, iron ore, chromite, diamonds, phosphate, and limestone processing. ... With this knowledge, they designed a ...

Sensorbased ore sorting can be used as a separation process for coarser grain sizes before the appliion of fine comminution and separation technologies and is applicable for a large variety of mineral raw materials. ... gold, copper, iron ore, chromite, diamonds, phosphate, and limestone processing. ... With this knowledge, they designed a ...

II. IMPORTANCE OF MINERALOGY IN MINERAL PROCESSING

a commercially viable method and is mainly based on the process of mineral liberation and the process of mineral separation. Though ore is mined with the highest efficiency of the technology, the excavated ore gets partly contaminated by the surrounding host rock (overburden) and the geological material closely associated with the ore during ...

a commercially viable method and is mainly based on the process of mineral liberation and the process of mineral separation. Though ore is mined with the highest efficiency of the technology, the excavated ore gets partly contaminated by the surrounding host rock (overburden) and the geological material closely associated with the ore during ...

tilden

While most North American iron mines use a magnetic separation process to upgrade magnetite ores, the initial Tilden flow sheet was new technology for processing nonmagnetic hematite ore. The hematite pit lies within a belt approximately 2 miles long and ½ mile wide.

While most North American iron mines use a magnetic separation process to upgrade magnetite ores, the initial Tilden flow sheet was new technology for processing nonmagnetic hematite ore. The hematite pit lies within a belt approximately 2 miles long and ½ mile wide.

الوظائف ذات الصلة

- كيفية بدء أعمال تعدين الفحم

- مطحنة الكرة عمان تستخدم

- المستخدمة محطات غسل تعدين الذهب للبيع في المملكة العربية السعودية

- عروض كسارة لفة

- موزعون لكسارة متنقلة في مصر

- عملية طحن خام الفضة

- كيفية بناء كسارة الصخور الصغيرة

- مطحنة الكرة رمل السيليكا طحن

- zenith كسارة وطاحونة الصين

- كسارة تصادمية مقاس 102 مم

- orbit pump manufacturing ltd

- verre machine de concasseur sa

- mobile crusher shanghsi

- specification of skd crusher tph

- the best selling cone crusher in china

- ondorhaan tangible benefits

- anthracite coal for home heating

- partners for stone quarry market in ghana

- cost for ethiopia granite crushing

- german rock crushing equipment manufacturers

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher