ball mill model variable speed

Ball Milling The Role of Media and Bead Mills

The VMAGetzmann basket mill consists of a stainlesssteel cylinder with an opening at the top and a sieve filter on the bottom. The standard diameter size of the grinding media is mm. however, it can be ordered to use mm bead size. Since the Getzmann basket mill is attached to a HighSpeed Disperser model, those with an adapter allow ...

The VMAGetzmann basket mill consists of a stainlesssteel cylinder with an opening at the top and a sieve filter on the bottom. The standard diameter size of the grinding media is mm. however, it can be ordered to use mm bead size. Since the Getzmann basket mill is attached to a HighSpeed Disperser model, those with an adapter allow ...

Variable Speed Drives

Advantages of using a Variable Speed Drive (VSD) VSD Benefits. Variable Speed Drives are probably the best method for controlling motor speed in response to varying process demands. These small decreases in the speed of pumps and fans or the pressure of pumps could lead to large decreases in energy use (and thus electricity costs).

Advantages of using a Variable Speed Drive (VSD) VSD Benefits. Variable Speed Drives are probably the best method for controlling motor speed in response to varying process demands. These small decreases in the speed of pumps and fans or the pressure of pumps could lead to large decreases in energy use (and thus electricity costs).

Development of operation strategies for variable speed ...

Development of operation strategies for variable speed ball mills. Creator. Liu, Sijia. Publisher. University of British Columbia. Date Issued. 2018. Description. Mineral processing productivity relates to a range of operating parameters, including production rate, product grind size, and energy efficiency.

Development of operation strategies for variable speed ball mills. Creator. Liu, Sijia. Publisher. University of British Columbia. Date Issued. 2018. Description. Mineral processing productivity relates to a range of operating parameters, including production rate, product grind size, and energy efficiency.

Variable Speed SAG Mill

22/09/2018 · Examples of the power requirement developed by a mill charge as mill speed increases have been added for a 10% v/v ball charge at different total mill charge volumes ranging from 1530% v/v. It can be seen that the risk of improper selection of nominal (or rated) motor power and speed can be considerable if an appreciation of how the ore is (or ...

22/09/2018 · Examples of the power requirement developed by a mill charge as mill speed increases have been added for a 10% v/v ball charge at different total mill charge volumes ranging from 1530% v/v. It can be seen that the risk of improper selection of nominal (or rated) motor power and speed can be considerable if an appreciation of how the ore is (or ...

Alliant Mill Problem

01/10/2006 · Alliant Mill Problem. I have an Alliant 2 Hp, variable speed mill, mn 42VC circa 1984. Several months ago, I don't use it much, the head got noisy and continued to get worse until I decided that it was time to tear it apart or this head was going to self destruct. I figured the usual bushing problems, what I found was much worse.

01/10/2006 · Alliant Mill Problem. I have an Alliant 2 Hp, variable speed mill, mn 42VC circa 1984. Several months ago, I don't use it much, the head got noisy and continued to get worse until I decided that it was time to tear it apart or this head was going to self destruct. I figured the usual bushing problems, what I found was much worse.

SAG Mill Optimization using Model Predictive Control

SAG mill, model predictive control, MPC, expert systems, optimization, Laguerre . ... distribution or mill rotation speed are also included in the control design, then the expert rules become even ... complete mathematical development of the control law used in the single variable .

SAG mill, model predictive control, MPC, expert systems, optimization, Laguerre . ... distribution or mill rotation speed are also included in the control design, then the expert rules become even ... complete mathematical development of the control law used in the single variable .

Ball End Mills | McMasterCarr

FastCutting Carbide Ball End Mills. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life. Made of solid carbide, they are harder, stronger, and more wear resistant than highspeed steel and cobalt steel for the longest life and best finish on hard material.

FastCutting Carbide Ball End Mills. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life. Made of solid carbide, they are harder, stronger, and more wear resistant than highspeed steel and cobalt steel for the longest life and best finish on hard material.

Mill Speed as a Manipulated Variable for Ball Mill ...

01/01/1983 · Afton claims that the variable mill speed has been useful for preventing liner wear while processing soft ore (Pazour, 1978). Sydvaranger processes iron ore through a 21 by 33foot variable speed ball mill. The speed range of this mill is from 62 to 82 percent of critical, with normal operating speed at 78 percent.

01/01/1983 · Afton claims that the variable mill speed has been useful for preventing liner wear while processing soft ore (Pazour, 1978). Sydvaranger processes iron ore through a 21 by 33foot variable speed ball mill. The speed range of this mill is from 62 to 82 percent of critical, with normal operating speed at 78 percent.

The working principle of ball mill

22/05/2019 · Mainly the rotation speed of the ball mill, the size and number of the grinding body, the volume of the object to be polished, the grinding medium and the grinding time. 1. the speed of the ball mill. When the ball mill rotates, the ball movement in the barrel may have three states (pic 8 .

22/05/2019 · Mainly the rotation speed of the ball mill, the size and number of the grinding body, the volume of the object to be polished, the grinding medium and the grinding time. 1. the speed of the ball mill. When the ball mill rotates, the ball movement in the barrel may have three states (pic 8 .

Influences of operating parameters on dry ball mill ...

Conventional ball mill A laboratory batch scale conventional ball mill which is made of stainless steel with the internal dimensions of 200 × 200 mm and the volume of 6283 cm3 was utilized in grinding tests. There is no lifter design in the grinding tank. The mill is driven by a kW variable speed motor.

Conventional ball mill A laboratory batch scale conventional ball mill which is made of stainless steel with the internal dimensions of 200 × 200 mm and the volume of 6283 cm3 was utilized in grinding tests. There is no lifter design in the grinding tank. The mill is driven by a kW variable speed motor.

ball mill model

ball mill model. This ball mill and rod mill power draw model is based on a torque model and empirical measurements made by the Equipment Company for use by its sales representatives to size grinding mills. Slight differences in the equations used allow rod mills, dry ball mills and wet overflow and grate ball mills to be sized.

ball mill model. This ball mill and rod mill power draw model is based on a torque model and empirical measurements made by the Equipment Company for use by its sales representatives to size grinding mills. Slight differences in the equations used allow rod mills, dry ball mills and wet overflow and grate ball mills to be sized.

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Breakage mechanisms in a ball mill 22 First order reaction model applied to milling 24 Grinding rate versus particle size for a given ball diameter 25 Cumulative breakage function versus relative size 28 Predicted variation of S i values with ball .

Breakage mechanisms in a ball mill 22 First order reaction model applied to milling 24 Grinding rate versus particle size for a given ball diameter 25 Cumulative breakage function versus relative size 28 Predicted variation of S i values with ball .

BMPTA01 BALL MILLS JIGGER ARMS

Ball Mill Porcelain Jars and Balls BMPTA02 BALL MILLS JIGGER ARMS. Motor . PTA01 115V (60Hz) 180W, PTA02 115V (60Hz) 180W ... This SPACESAVING rack will allow for variable speed milling. The rack accommodates jars from 3" ½" to 9" diameter up to 10" long. ... › Model construction; heavyduty cast iron

Ball Mill Porcelain Jars and Balls BMPTA02 BALL MILLS JIGGER ARMS. Motor . PTA01 115V (60Hz) 180W, PTA02 115V (60Hz) 180W ... This SPACESAVING rack will allow for variable speed milling. The rack accommodates jars from 3" ½" to 9" diameter up to 10" long. ... › Model construction; heavyduty cast iron

Variablespeed quantitative feeding system of ball mill ...

The invention provides a variablespeed quantitative feeding system of a ball mill. The variablespeed quantitative feeding system comprises a handoperated butterfly valve, a flexible coupling, an enclosed feeding screw, a connector, a speed reducer, a variablespeed motor and a frequency converter, wherein the enclosed feeding screw is inserted into the drum of the ball mill, a flange .

The invention provides a variablespeed quantitative feeding system of a ball mill. The variablespeed quantitative feeding system comprises a handoperated butterfly valve, a flexible coupling, an enclosed feeding screw, a connector, a speed reducer, a variablespeed motor and a frequency converter, wherein the enclosed feeding screw is inserted into the drum of the ball mill, a flange .

The Evolution of Grinding Mill Power Models | SpringerLink

30/01/2019 · Hogg and Fuerstenau [] using an approximate model of the motion of the ball charge derived a simple equation relating mill power to mill dimensions, speed of rotation, and the ball filling this model, it was assumed that the charge consists of two distinct regions: a "static" region where particles do not move relative to the mill shell and a "shear" zone where particles .

30/01/2019 · Hogg and Fuerstenau [] using an approximate model of the motion of the ball charge derived a simple equation relating mill power to mill dimensions, speed of rotation, and the ball filling this model, it was assumed that the charge consists of two distinct regions: a "static" region where particles do not move relative to the mill shell and a "shear" zone where particles .

Single Ball Mill | Peter Pugger

Innovative design features, including variable speed control (can accommodate a large range of jar sizes), inverter controlled drive for high electrical efficiency, dropin slots for quick roller bar changeout, easily accessible roller shaft bands and wrapped in a beautiful Stainless Steel shroud making Peter Pugger's Single Ball Mill the first choice for smallscale to largeproduction ...

Innovative design features, including variable speed control (can accommodate a large range of jar sizes), inverter controlled drive for high electrical efficiency, dropin slots for quick roller bar changeout, easily accessible roller shaft bands and wrapped in a beautiful Stainless Steel shroud making Peter Pugger's Single Ball Mill the first choice for smallscale to largeproduction ...

ball mill modeling

Modelling of the HighEnergy Ball Milling Process. Modelling of the HighEnergy Ball Milling Process In this paper, the milling parameters of high energy ball mill (Fritsch Pulverisette 7) like vial geometry, number and size of balls and speed of the mill were modelled and discussed.

Modelling of the HighEnergy Ball Milling Process. Modelling of the HighEnergy Ball Milling Process In this paper, the milling parameters of high energy ball mill (Fritsch Pulverisette 7) like vial geometry, number and size of balls and speed of the mill were modelled and discussed.

Variables in Ball Mill Operation | Paul O. Abbe®

In ball milling of dry solids the main independent variables are mill diameter, mill speed, media size, solids loading and residence time. For most companies the production mill already exists so we can ignore mill diameter and focus on the other variables. Mill Speed is one variable that can often be easily changed with a variable frequency ...

In ball milling of dry solids the main independent variables are mill diameter, mill speed, media size, solids loading and residence time. For most companies the production mill already exists so we can ignore mill diameter and focus on the other variables. Mill Speed is one variable that can often be easily changed with a variable frequency ...

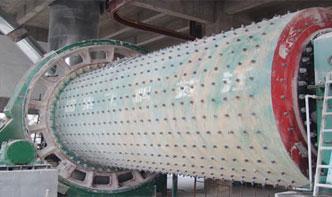

BALL MILL MODEL 3 VARIABLE SPEED | Capco Test Equipment

The Ball Mill Model 3 is designed for use with 5 to 35 litre Ball Mill machine has a roller speed from 0420RPM and can be adjusted by the speed controller. The technical spec is –. All Ball Mill Jars, charge set and accessories can be found under the Ball Mill Accessories tab.

The Ball Mill Model 3 is designed for use with 5 to 35 litre Ball Mill machine has a roller speed from 0420RPM and can be adjusted by the speed controller. The technical spec is –. All Ball Mill Jars, charge set and accessories can be found under the Ball Mill Accessories tab.

JTM4VS Variable Speed Vertical Milling ...

Precision bored and honed milling heads ensure quality cuts, and the threestage power downfeed with automatic stop makes the JET Variable Speed Milling Machines easy to use. Available in single or three phase power configurations, the JET JTM4VS Series mills are backed by the industry leading two year full service and parts warranty.

Precision bored and honed milling heads ensure quality cuts, and the threestage power downfeed with automatic stop makes the JET Variable Speed Milling Machines easy to use. Available in single or three phase power configurations, the JET JTM4VS Series mills are backed by the industry leading two year full service and parts warranty.

Ball Mill

18/11/2008 · The speed of the shell: The maximum speed avoiding centrifugal force, Where Mass of balls The bulk volume of the balls is {3045%} of the volume of the shell of the ball mill and the feed is filling the empty space between the balls where the static porosity is about 40%,and the balls charge is vary from 3045% 5.

18/11/2008 · The speed of the shell: The maximum speed avoiding centrifugal force, Where Mass of balls The bulk volume of the balls is {3045%} of the volume of the shell of the ball mill and the feed is filling the empty space between the balls where the static porosity is about 40%,and the balls charge is vary from 3045% 5.

الوظائف ذات الصلة

- مصنع كسارة الحجارة في هيماشال

- كسارة الحجر المصنعة في مصر

- معدات تعدين خام النيكل في الجزائر

- الغول أخبار التعدين في برن

- معدات الطحن السعر في الولايات المتحدة الأمريكية

- محطة معالجة الحصى المتنقلة

- كسارة الإطارات المطاطية الاسمنتية

- مختبر طاحونة مقياس السعر

- سعر كسارة خام الحديد المعدات في مصر

- تأثير أوزبكستان كسارة للبيع

- 4 roller pulvarazing lakshmi mill udaypurspares

- alumina aration from silica sand

- contour machine grinding stone crusher tdc r73005 747922 2 cbn 200

- chinois concasseur a percussion processeur de minerai de fer mobiles

- gambar mesin separator pasir zircon rileksanta

- gyratory crusher gravel

- broyeur de fer pour une capacité de 250 tonnes

- rock crusher sample resume

- future scope for stone crusher in india

- how to setup a cement factory in india and it s cost

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher