sticky material cone crushers problems

What to Know about Rock Crushers – Crusher Manufacturers ...

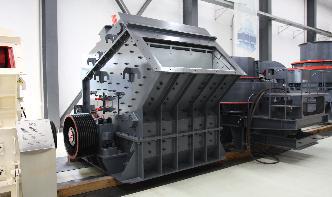

· What to Know about Rock Crushers. The rock crusher is the machine that is used for reducing huge rocks into rock dust, gravel or smaller pieces. These machines are often used to make the larger sized rocks into the smaller pieces without any extra human effort. This is one of the easiest methods for turning the larger items into smaller sizes ...

· What to Know about Rock Crushers. The rock crusher is the machine that is used for reducing huge rocks into rock dust, gravel or smaller pieces. These machines are often used to make the larger sized rocks into the smaller pieces without any extra human effort. This is one of the easiest methods for turning the larger items into smaller sizes ...

Products – Trimax Machinery – Simply Better Crushers

The Trimax NH Cone Crusher is suitable for tertiary crushing appliions. ... Attrition between grinding balls and feed material causes grinding into finer particles. ... The ADplus Hybrid SelfCleaning Screening System is the ideal solution for customers who frequently face problems when screening wet, sticky, and fine material.

The Trimax NH Cone Crusher is suitable for tertiary crushing appliions. ... Attrition between grinding balls and feed material causes grinding into finer particles. ... The ADplus Hybrid SelfCleaning Screening System is the ideal solution for customers who frequently face problems when screening wet, sticky, and fine material.

sticky material cone crushers problems

Sticky material cone crusher problems sticky material cone crusher problems,does wet, sticky or high clay ore create material handling issues at your of flow in cone crushers the possibility to simulate and predict cone crusher performance is of great interest for the development of crushers as well as for the design price.

Sticky material cone crusher problems sticky material cone crusher problems,does wet, sticky or high clay ore create material handling issues at your of flow in cone crushers the possibility to simulate and predict cone crusher performance is of great interest for the development of crushers as well as for the design price.

sticky material cone crushers problems

· Sticky Material Cone Crushers Problems Sticky material cone crusher problems aib010 s replace cones for crushing iron ore omes to crushing and screening processesater is widely used to flush sticky material through some crushers and this in turn causes problems later in theet price and support online sticky wet material crusher .

· Sticky Material Cone Crushers Problems Sticky material cone crusher problems aib010 s replace cones for crushing iron ore omes to crushing and screening processesater is widely used to flush sticky material through some crushers and this in turn causes problems later in theet price and support online sticky wet material crusher .

Sticky Material Cone Crushers Problems

Sticky material cone crushers material cone crushers cone crusher for crushing iron oremining wet sticky materials usually mean trouble when it comes to crushing and screening process water is widely used to flush sticky material through some crushers and this in turn causes problems later in the crushing circuit .

Sticky material cone crushers material cone crushers cone crusher for crushing iron oremining wet sticky materials usually mean trouble when it comes to crushing and screening process water is widely used to flush sticky material through some crushers and this in turn causes problems later in the crushing circuit .

Gyratory Crushers

· Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended. Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing soft and medium limestone and materials .

· Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended. Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing soft and medium limestone and materials .

A CASE STUDY ON THE PREVENTION OF SEGREGATION .

During startup of a new BolzSummix® conical screw dryer, the bulk product agglomerated due to its sticky nature during a critical phase of the drying cycle. Down stream from the dryer, in the feed chute to the tabletting machine, segregation of the coarse product from the fine gave validation problems. This case study shows, that by

During startup of a new BolzSummix® conical screw dryer, the bulk product agglomerated due to its sticky nature during a critical phase of the drying cycle. Down stream from the dryer, in the feed chute to the tabletting machine, segregation of the coarse product from the fine gave validation problems. This case study shows, that by

Tillicoultry Quarries invest in Finlay | Hub4

· This material is then picked up by wheel loader and fed into the Finlay train starting with the first C1550 cone crusher. Working in closed circuit, material is then fed into the 693+ screener with all the +20mm then fed into the second C1550 for further reduction and then screened by the 694+ screener for the 6 and 10mm.

· This material is then picked up by wheel loader and fed into the Finlay train starting with the first C1550 cone crusher. Working in closed circuit, material is then fed into the 693+ screener with all the +20mm then fed into the second C1550 for further reduction and then screened by the 694+ screener for the 6 and 10mm.

MORE SOLUTIONS TO STICKY PROBLEMS: TABLE OF CONTENTS

Cone/Plate Geometry..... 5 TBar Spindles ... NonFlowing Sample Materials ..... 8 Helipath Stand..... 8 Spiral Adapter ... surement problems; S by explaining the basic principles of rheology

Cone/Plate Geometry..... 5 TBar Spindles ... NonFlowing Sample Materials ..... 8 Helipath Stand..... 8 Spiral Adapter ... surement problems; S by explaining the basic principles of rheology

Tips to maximize crushing efficiency

· Uniform distribution of feed material around the cone crusher inlet is good practice. This allows production of a consistent product, as well as efficient, reliable operation of the crusher. Choke feeding is important for cone crushers because it maintains a good particle shape by facilitating an interparticle crushing action.

· Uniform distribution of feed material around the cone crusher inlet is good practice. This allows production of a consistent product, as well as efficient, reliable operation of the crusher. Choke feeding is important for cone crushers because it maintains a good particle shape by facilitating an interparticle crushing action.

PQ University Lesson 7 Crushing Secondary Breaking ...

· They are compression crushers that generally provide reduction ratios of 6to1 to 4to1. Cone crushers are used in secondary, tertiary and quaternary stages. With proper chokefeed, conespeed and reductionratio settings, cone crushers will efficiently produce material that is high quality and cubical in nature.

· They are compression crushers that generally provide reduction ratios of 6to1 to 4to1. Cone crushers are used in secondary, tertiary and quaternary stages. With proper chokefeed, conespeed and reductionratio settings, cone crushers will efficiently produce material that is high quality and cubical in nature.

Striker | Built To Last

We aim to increase your production and profits through understanding your rock and appliion. Our experienced crushing and screening experts tailor every Striker crusher or screen to your appliion. All Striker mobile crushers and screens are designed and manufactured in our globally facilities. Talk to our team and let us help you make the right decision.

We aim to increase your production and profits through understanding your rock and appliion. Our experienced crushing and screening experts tailor every Striker crusher or screen to your appliion. All Striker mobile crushers and screens are designed and manufactured in our globally facilities. Talk to our team and let us help you make the right decision.

Battling Buildups and Blockages | Feed Grain Magazine

· Battling Buildups and Blockages. Routine bin and silo cleanouts can help keep product accumulations at bay. Keeping the inside of bulk storage bins and silos clean is an ongoing challenge for many feed mills and grain elevators, especially since a number of ingredients used in the feed and grain industries are prone to buildups that can ...

· Battling Buildups and Blockages. Routine bin and silo cleanouts can help keep product accumulations at bay. Keeping the inside of bulk storage bins and silos clean is an ongoing challenge for many feed mills and grain elevators, especially since a number of ingredients used in the feed and grain industries are prone to buildups that can ...

White and Sticky Plant Diseases | Home Guides | SF Gate

· White and Sticky Plant Diseases. If your plants are covered in white, sticky material, you can relax a little: These plants aren't diseased. They're suffering from .

· White and Sticky Plant Diseases. If your plants are covered in white, sticky material, you can relax a little: These plants aren't diseased. They're suffering from .

A Review on Cryogenic Grinding

420| MITCOE, DIAT, Pune, AMET2017, IJCET INPRESSO Special Issue7 (March 2017) A Review on Cryogenic Grinding Hemantkumar Junghare*, Mayur Hamjade, ... the material gets crushed ... the material gets crushed between the studs and cones out through an optional sieve as a ground the bottom of the mills a collecting bin is housed ...

420| MITCOE, DIAT, Pune, AMET2017, IJCET INPRESSO Special Issue7 (March 2017) A Review on Cryogenic Grinding Hemantkumar Junghare*, Mayur Hamjade, ... the material gets crushed ... the material gets crushed between the studs and cones out through an optional sieve as a ground the bottom of the mills a collecting bin is housed ...

Rubber | Diamond Equipment Group

The ® rubber product range — Premium wear resistant rubber for sliding and wet abrasion service • ® premium rubber: A 95% natural rubber product manufactured using a proprietary Liquid Phase Compounding process, that exhibits outstanding resilience, strength and resistance to cutting, tearing and abrasion. With ® premium rubber there is no equivalent.

The ® rubber product range — Premium wear resistant rubber for sliding and wet abrasion service • ® premium rubber: A 95% natural rubber product manufactured using a proprietary Liquid Phase Compounding process, that exhibits outstanding resilience, strength and resistance to cutting, tearing and abrasion. With ® premium rubber there is no equivalent.

mmon problems in ne crusher

The Common Questions of Cone Crusher and Corresponding ... Nov 25, 2019 The cone crusher is one of the most common ones and often used as the secondary crushing machine in the whole stone crushing process. Cone crusher working site. During the operation of the cone crusher, the operator often encounters a variety of problems.

The Common Questions of Cone Crusher and Corresponding ... Nov 25, 2019 The cone crusher is one of the most common ones and often used as the secondary crushing machine in the whole stone crushing process. Cone crusher working site. During the operation of the cone crusher, the operator often encounters a variety of problems.

QH441OperationManual

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

4 Types of Stone Crushers' Maintenance and Efficient ...

· Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures mediumhard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenance. 6 Tips to help you prolong the concrusher's service life:

· Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures mediumhard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenance. 6 Tips to help you prolong the concrusher's service life:

Crushers

Both cone and gyratory crushers, as shown in Figure, have an oscillating shaft. The material is crushed in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft assembly.

Both cone and gyratory crushers, as shown in Figure, have an oscillating shaft. The material is crushed in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft assembly.

Impact crusher

The crusher therefore has to handle feed that contains larger blocks as well as some sticky materials. Our EV Hammer Impact Crusher is a proven, reliable and costeffective impact crusher that help to overcome these crushing challenges. Combatting large feed block challenges In traditional hammer crushers with a top inlet, introducing large ...

The crusher therefore has to handle feed that contains larger blocks as well as some sticky materials. Our EV Hammer Impact Crusher is a proven, reliable and costeffective impact crusher that help to overcome these crushing challenges. Combatting large feed block challenges In traditional hammer crushers with a top inlet, introducing large ...

الوظائف ذات الصلة

- أكبر مصنعي الكسارات في أمريكا الشمالية

- الكسارة المتنقلة الزاحفة المصنوعة في ألمانيا

- المستوردين آلة سر سنغافورة

- بيع كسارة الفك المحمولة مصر

- ناقل الحزام لسعة منخفضة

- ساحة كوستوداك برودوكسيون

- عملية طحن الرمل الاصطناعي للبيع

- صور كسارة مطحنة الأسمنت

- آلة كسارة الحجر المرحلة puzzolana 200tph

- مقاسات الركام الحجري

- peru mina de cobre moinho

- instruction manual cone crusher

- price of grinding mill in grinding limestone

- safety conveyor belt presentation

- efek dari grinding crusher

- concasseur a rouleaux a double rouleau

- flex wet stone grinder europe syria

- tahina final grinding ball mill

- jaw crusher model kys 16x10

- grinding mill norberg c105 jaw crusher spare parts catalogue

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher