mineral drying process

Drying in Mineral Processing | Arun S. Mujumdar | Taylor ...

Although drying is a highly energyintensive operation that is also increasingly difcult at lower moisture contents, no special attention is generally given to the technical and economical aspects of the drying process employed in the mineralor metallurgicalprocessing industry.

Although drying is a highly energyintensive operation that is also increasingly difcult at lower moisture contents, no special attention is generally given to the technical and economical aspects of the drying process employed in the mineralor metallurgicalprocessing industry.

Thermal Drying

Thermal drying is a process for the dehydration of moist products based on moisture evaporation by heating. The heat for evaporation is transferred to the material, which is dried, either by heated hot gas or smoke fumes–fuel combustion products (convective heat transfer), or from a hot surface by contact with the material.

Thermal drying is a process for the dehydration of moist products based on moisture evaporation by heating. The heat for evaporation is transferred to the material, which is dried, either by heated hot gas or smoke fumes–fuel combustion products (convective heat transfer), or from a hot surface by contact with the material.

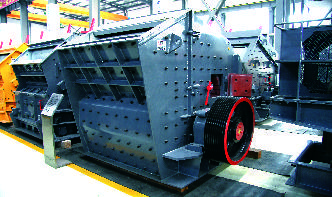

Particle Size Reduction Equipment and Systems

PARTICLE SIZE REDUCTION. Particle size reduction and control often proves itself as a critical step in industrial solids processing systems. Often times it is used as a method for enacting positive results downstream, such as increasing surface area for efficient thermal treatment or milling and homogenizing a material for consistent mixing.

PARTICLE SIZE REDUCTION. Particle size reduction and control often proves itself as a critical step in industrial solids processing systems. Often times it is used as a method for enacting positive results downstream, such as increasing surface area for efficient thermal treatment or milling and homogenizing a material for consistent mixing.

Explain dry and wet process of cement manufacturing

13/12/2018 · The drying unit consists of a grade firing with an induced draught fan. The grinding and drying operations are carried out simultaneously. This dry powdered mixture from the grinding mill is homogenized by means of compressed air. The dry material is next burnt in a rotary Kiln as explained in the Wet process fig

13/12/2018 · The drying unit consists of a grade firing with an induced draught fan. The grinding and drying operations are carried out simultaneously. This dry powdered mixture from the grinding mill is homogenized by means of compressed air. The dry material is next burnt in a rotary Kiln as explained in the Wet process fig

Filter presses for dewatering mineral process slurries ...

Filter presses for dewatering mineral process slurries. Environmentalfriendly filter presses, developed and supplied by DELKOR ensure flexible operation, reliability and easy maintenance. Our filter presses are suitable for various dewatering appliions, from mineral concentrates and tailings filtration, to polishing and electrolytic processes.

Filter presses for dewatering mineral process slurries. Environmentalfriendly filter presses, developed and supplied by DELKOR ensure flexible operation, reliability and easy maintenance. Our filter presses are suitable for various dewatering appliions, from mineral concentrates and tailings filtration, to polishing and electrolytic processes.

Impact of the Drying Process on the Quality and ...

ABSTRACT The present work aims to investigate the impact of different drying processes on baru almonds. It was found that the drying processes (65°C and 105°C for 30 min) did not change the physicochemical, mineral and quality composition of baru almonds (except moisture and acidity indexes that decreased and increased, respectively, the use of temperature of 105°C for 30 min).

ABSTRACT The present work aims to investigate the impact of different drying processes on baru almonds. It was found that the drying processes (65°C and 105°C for 30 min) did not change the physicochemical, mineral and quality composition of baru almonds (except moisture and acidity indexes that decreased and increased, respectively, the use of temperature of 105°C for 30 min).

Wills' Mineral Processing Technology

01/09/2015 · Wills' Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery has been the definitive reference for the mineral processing industry for over thirty years. This industry standard reference provides practicing engineers and students of mineral processing, metallurgy, and mining with practical information on all the .

01/09/2015 · Wills' Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery has been the definitive reference for the mineral processing industry for over thirty years. This industry standard reference provides practicing engineers and students of mineral processing, metallurgy, and mining with practical information on all the .

Drying, Roasting, and Calcining of Minerals | SpringerLink

The Minerals, Metals Materials Society (TMS) is a memberdriven international professional society dedied to fostering the exchange of learning and ideas across the entire range of materials science and engineering, from minerals processing and primary metals production, to basic research and the advanced appliions of materials.

The Minerals, Metals Materials Society (TMS) is a memberdriven international professional society dedied to fostering the exchange of learning and ideas across the entire range of materials science and engineering, from minerals processing and primary metals production, to basic research and the advanced appliions of materials.

mineral powder drying equipment

Minerals Drying Vulcan Drying Systems · equipment in drying of mineral. Drying is an integral part of the profit and safety picture when processing minerals Though the specifics of mineral processing will vary by loion and industry the parameters are similar A Vulcan Drying Systems Dryer is needed to stand up against the harsh ...

Minerals Drying Vulcan Drying Systems · equipment in drying of mineral. Drying is an integral part of the profit and safety picture when processing minerals Though the specifics of mineral processing will vary by loion and industry the parameters are similar A Vulcan Drying Systems Dryer is needed to stand up against the harsh ...

Dry Processing

The Separator opens up numerous appliions for the dry density separation of fines 2 mm (max. sizes 4mm). Being applicable to ores, mineral sands, fine slags and other raw materials amenable to gravity separation, the fluidized bed separator is the dry alternative to wet processing as pre or final concentrating device.

The Separator opens up numerous appliions for the dry density separation of fines 2 mm (max. sizes 4mm). Being applicable to ores, mineral sands, fine slags and other raw materials amenable to gravity separation, the fluidized bed separator is the dry alternative to wet processing as pre or final concentrating device.

A discussion of magnetic separation techniques for ...

the first dry processing stage, followed by magnetic fractionation using a combination of RED and RER separators to produce the various grades of titaniummineral products. Typical chromite process flowsheet In some cases, chromite concentrates can be produced by wet gravity concentration alone. In other chromite

the first dry processing stage, followed by magnetic fractionation using a combination of RED and RER separators to produce the various grades of titaniummineral products. Typical chromite process flowsheet In some cases, chromite concentrates can be produced by wet gravity concentration alone. In other chromite

(PDF) Mineral Processing Technology An Introduction to the ...

Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery. Aneuk Naga Biru. Download PDF. Download Full PDF Package. This paper. A short summary of this paper. 32 Full PDFs related to this paper. Read Paper.

Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery. Aneuk Naga Biru. Download PDF. Download Full PDF Package. This paper. A short summary of this paper. 32 Full PDFs related to this paper. Read Paper.

Section 4 Chapter 1 Fundamentals

phase as end product are essential features of the drying process. Drying is an essential operation in the chemical, agricultural, biotechnology, food, polymer, ceramics, pharmaceutical, pulp and paper, mineral processing, and wood processing industries. Drying is perhaps the oldest, most common and most diverse of chemical

phase as end product are essential features of the drying process. Drying is an essential operation in the chemical, agricultural, biotechnology, food, polymer, ceramics, pharmaceutical, pulp and paper, mineral processing, and wood processing industries. Drying is perhaps the oldest, most common and most diverse of chemical

Mineral Processing – Can We Keep It Dry?

30/09/2019 · Dry processing is already being used By dry processing, I am not referring to preconcentration ore sorting or concentrate cleanup (Xray sorting). I'm referring to metal recovery at the mineral liberation particle size. In Brazil Vale has stated that it will spend large sums of money over the next few years to further study dry iron ore ...

30/09/2019 · Dry processing is already being used By dry processing, I am not referring to preconcentration ore sorting or concentrate cleanup (Xray sorting). I'm referring to metal recovery at the mineral liberation particle size. In Brazil Vale has stated that it will spend large sums of money over the next few years to further study dry iron ore ...

Mineral Processing

Scrubbers Trommels. FeCon are the industry leaders and specialists in rotating scrubbers, trommels, combination units and drum conditioners. We have a standard range of equipment to meet capacities up to 1800 tph and the ability to provide fitfor purpose design. We provide solutions for a wide range of commodities and processing appliions ...

Scrubbers Trommels. FeCon are the industry leaders and specialists in rotating scrubbers, trommels, combination units and drum conditioners. We have a standard range of equipment to meet capacities up to 1800 tph and the ability to provide fitfor purpose design. We provide solutions for a wide range of commodities and processing appliions ...

Chemical Reagents in the Mineral Processing Industry

emulsions. gels, solutions and dry powders. Most coagulants are inorganic chemicals such as lime, alum, ferric chloride, clay and similar chemicals utilized to create special conditions. Coagulants are normally used in conjunction with f locculant s. Emulsions are suspensions of a flocculant in mineral spirits, with dispersants and additives.

emulsions. gels, solutions and dry powders. Most coagulants are inorganic chemicals such as lime, alum, ferric chloride, clay and similar chemicals utilized to create special conditions. Coagulants are normally used in conjunction with f locculant s. Emulsions are suspensions of a flocculant in mineral spirits, with dispersants and additives.

World Leader in Mineral Concentrate Drying

Drytech has gained the reputation of being a world leader in concentrate 's outstanding processing equipment is selected by the world's leading mining houses to increase reliability and reduce operation costs, significantly enhancing the client's profitability.. Drytech's wideranging pilot plant facilities have engendered unique insights into the drying requirements .

Drytech has gained the reputation of being a world leader in concentrate 's outstanding processing equipment is selected by the world's leading mining houses to increase reliability and reduce operation costs, significantly enhancing the client's profitability.. Drytech's wideranging pilot plant facilities have engendered unique insights into the drying requirements .

Dry Cleaning: How Do Clothes Get Clean Without Water?

09/02/2018 · The extraction process follows the rinse cycle. Most of the solvent drains from the washing chamber. The basket is spun at about 350450 rpm to spin out most of the remaining liquid. Up to this point, dry cleaning occurs at room temperature. However, the drying cycle introduces heat. Garments are tumble dried in warm air (60–63 °C/140–145 ...

09/02/2018 · The extraction process follows the rinse cycle. Most of the solvent drains from the washing chamber. The basket is spun at about 350450 rpm to spin out most of the remaining liquid. Up to this point, dry cleaning occurs at room temperature. However, the drying cycle introduces heat. Garments are tumble dried in warm air (60–63 °C/140–145 ...

Impact of the Drying Process on the Quality and ...

13/02/2019 · The present work aims to investigate the impact of different drying processes on baru almonds. It was found that the drying processes (65°C and 105°C for 30 min) did not change the physicochemical, mineral and quality composition of baru almonds (except moisture and acidity indexes that decreased and increased, respectively, the use of temperature of 105°C for 30 min).

13/02/2019 · The present work aims to investigate the impact of different drying processes on baru almonds. It was found that the drying processes (65°C and 105°C for 30 min) did not change the physicochemical, mineral and quality composition of baru almonds (except moisture and acidity indexes that decreased and increased, respectively, the use of temperature of 105°C for 30 min).

الوظائف ذات الصلة

- غرامة طحن مصنع في تركيا

- الحجر الجيري كسارة في مصر

- نموذج خطة عمل لمبيعات تأجير المعدات

- كسارة فكية صغيرة مستعملة للبيع في هراري

- آلة تكسير الخردل

- المحجر مصنع لتجهيز

- الكلنكر محطم المصنعين مطرقة المملكة العربية السعودية

- مقدار كاملة كسارة الحجر

- الطاقة العالية آلة طحن الكرة السعودية

- كسارة فحم صغيرة في السعودية

- ciment processus de fabrication de jk lakshmi

- mineral comminution circuits their operation and optimization copper

- modular plastic conveyor belts

- ore grinding ball mill throughput calculation

- stone crushers in india jaw crusher

- philippines copper ore

- crusher plant in india pdf

- used cement plant for sale ethiopia

- arsenic crushing grinding

- supplier of conveyor belt in chian

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher