ore crushing process metal ball

process of crushing ores

process of crushing ores. process of crushing ores supremewheelscoza crushing process of iron ore tfg iron ore crushing process crusherquartzcrusher brief introduction about iron ore Iron Fe is a metallic element and composes about 5 of the Earths crust When pure it is a dark silverygray metal Get More Info image crushing iron ore crusher process Odysseus Project

process of crushing ores. process of crushing ores supremewheelscoza crushing process of iron ore tfg iron ore crushing process crusherquartzcrusher brief introduction about iron ore Iron Fe is a metallic element and composes about 5 of the Earths crust When pure it is a dark silverygray metal Get More Info image crushing iron ore crusher process Odysseus Project

A Look at the Process of Pelletizing Iron Ore for Steel ...

Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores. This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron ore.

Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores. This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron ore.

Crushing Process Of Ores

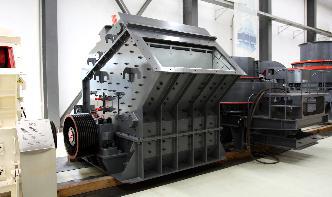

crushing process of ni ores Trends in the Crushing of Mineral Ores Mineral Processing. · Crushing is an important step in the complex process of mineral processing (Fig. 1). In open pit mines, rock chunks with edge lengths of 2 m have to be processed. In underground mines, the biggest chunk sizes are about m.

crushing process of ni ores Trends in the Crushing of Mineral Ores Mineral Processing. · Crushing is an important step in the complex process of mineral processing (Fig. 1). In open pit mines, rock chunks with edge lengths of 2 m have to be processed. In underground mines, the biggest chunk sizes are about m.

(PDF) Comminution in mineral processing

The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of treating crude material from excavation into mineral ...

The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of treating crude material from excavation into mineral ...

Copper Mining and Extraction Sulfide Ores

Processing Stages. Stage 1: Crushing and grinding The ore from the mine contains about 2% copper. To get at the copper the first stage is crushing in huge cylindrical ball mills. Ball mills crush the ore into a fine powder. (Courtesy of Rio Tinto.) Stage 2: Froth flotation

Processing Stages. Stage 1: Crushing and grinding The ore from the mine contains about 2% copper. To get at the copper the first stage is crushing in huge cylindrical ball mills. Ball mills crush the ore into a fine powder. (Courtesy of Rio Tinto.) Stage 2: Froth flotation

Lead and Zinc

the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semiautogenous mills (steel balls are added to the ore).

the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semiautogenous mills (steel balls are added to the ore).

Crushing Process Of Ni Ores

Crushing Process Of Ni Ores. Gold ores should firstly be through crushing and grinding process into fine particles Manganese Manganese is the fourth most used metal in terms of tonnage, its just behind copper Nickel Nickel mineral mainly includes nickel oxide ore and coppernickel sulphide Silver Silver is can be obtained through the beneficiation process skill Tin

Crushing Process Of Ni Ores. Gold ores should firstly be through crushing and grinding process into fine particles Manganese Manganese is the fourth most used metal in terms of tonnage, its just behind copper Nickel Nickel mineral mainly includes nickel oxide ore and coppernickel sulphide Silver Silver is can be obtained through the beneficiation process skill Tin

Crushing, Grinding and Concentration of the Ore ...

02/04/2020 · 4) Purifiion or refining of the metal (1) Crushing and Grinding of the Ore. The ores occur in nature as huge lumps. They are broken to small pieces with the help of crushers or grinders. These pieces are then reduced to fine powder with the help of a ball mill or stamp mill. This process is called pulverisation. (2) Concentration of Ore or ...

02/04/2020 · 4) Purifiion or refining of the metal (1) Crushing and Grinding of the Ore. The ores occur in nature as huge lumps. They are broken to small pieces with the help of crushers or grinders. These pieces are then reduced to fine powder with the help of a ball mill or stamp mill. This process is called pulverisation. (2) Concentration of Ore or ...

Copper Mining and Processing: Processing Copper Ores ...

This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis. Following mining, transporting, and crushing to a consistent gravel or golf ballsize, the crushed ore is further processed at a mill ...

This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis. Following mining, transporting, and crushing to a consistent gravel or golf ballsize, the crushed ore is further processed at a mill ...

Iron Ores Washer Process

Sandur Manganese and Iron Ores . Beneficiation of Manganese and Iron Ore. In the same way, the reserves of iron ore too, can go through a beneficiation process to upgrade its quality. The enriched output would be suitable for both sinter and pellet production.

Sandur Manganese and Iron Ores . Beneficiation of Manganese and Iron Ore. In the same way, the reserves of iron ore too, can go through a beneficiation process to upgrade its quality. The enriched output would be suitable for both sinter and pellet production.

crushing process of iron ores

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin . Sep 23, 2019 Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin . Sep 23, 2019 Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore

Ore crusher balls

Ore crusher balls Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ore crusher balls, quarry, aggregate, and different kinds of minerals.

Ore crusher balls Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ore crusher balls, quarry, aggregate, and different kinds of minerals.

Ball Mill Used in Minerals Processing Plant | Prominer ...

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

Glossary of Mining Terms

Ball mill A steel cylinder filled with steel balls into which crushed ore is fed. The ball mill is rotated, causing the balls to cascade and grind the ore. Banded iron formation A bedded deposit of iron minerals. Basalt An extrusive volcanic rock composed primarily of plagioclase, pyroxene and some olivine.

Ball mill A steel cylinder filled with steel balls into which crushed ore is fed. The ball mill is rotated, causing the balls to cascade and grind the ore. Banded iron formation A bedded deposit of iron minerals. Basalt An extrusive volcanic rock composed primarily of plagioclase, pyroxene and some olivine.

Processing

30/06/2021 · We have four inpit crushers, each standing seven stories high and able to crush more than 4,000 tonnes of ore an hour – these are the largest inpit crushers in Australia. The crushers deposit the ore onto one of two overland conveyors, each kilometres in length, which transports the ore up to the coarse ore stockpile at the Processing ...

30/06/2021 · We have four inpit crushers, each standing seven stories high and able to crush more than 4,000 tonnes of ore an hour – these are the largest inpit crushers in Australia. The crushers deposit the ore onto one of two overland conveyors, each kilometres in length, which transports the ore up to the coarse ore stockpile at the Processing ...

Grinding Crushing Mill

Heavy pulp density for maximum ore processed per gallon of liquid. The System is fully automated. Insitu leaching eliminates external leaching componentry and helps control chemistry. Leaching Appliions: The VIBRADRUM® in a wet grind leaching appliion provides efficient chemomechanical processing of ore bodies for precious metal recovery.

Heavy pulp density for maximum ore processed per gallon of liquid. The System is fully automated. Insitu leaching eliminates external leaching componentry and helps control chemistry. Leaching Appliions: The VIBRADRUM® in a wet grind leaching appliion provides efficient chemomechanical processing of ore bodies for precious metal recovery.

First Quantum Minerals Ltd.

Enterprise ore will be delivered to a dedied system of dual primary crushers, crushed ore stockpile and conveying. Up to 4 million tonnes per year of nickel ore will be treated in a SAG – ball milling circuit with pebble crushing, flash flotation and nickel flotation.

Enterprise ore will be delivered to a dedied system of dual primary crushers, crushed ore stockpile and conveying. Up to 4 million tonnes per year of nickel ore will be treated in a SAG – ball milling circuit with pebble crushing, flash flotation and nickel flotation.

Extracting ores | Mining of mineral resources | Siyavula

Inside a ball mill, the balls move round in a circle as the mill turns, crushing the ore into a powder. This process of reducing the size of the rocks requires a lot of energy. Just image how hard it is to break a rock. How much more energy do you think is needed to crush a rock until it is like sand?

Inside a ball mill, the balls move round in a circle as the mill turns, crushing the ore into a powder. This process of reducing the size of the rocks requires a lot of energy. Just image how hard it is to break a rock. How much more energy do you think is needed to crush a rock until it is like sand?

(PDF) Calculating the value of iron ores in ironmaking and ...

The. main steps in the sintering process are: Blending – a range of iron ore fi nes from different suppliers. are blended with steelworks recycle materials. Mixing – a reductant such as coke ...

The. main steps in the sintering process are: Blending – a range of iron ore fi nes from different suppliers. are blended with steelworks recycle materials. Mixing – a reductant such as coke ...

Tungsten Extraction Process

09/03/2016 · The Beneficiation flowsheet shown with this study is particularly adapted to the concentration of tungsten ore in small tonnages. Tungsten minerals are generally in the friable class and therefore concentrating processes are hindered by the excess amount of fines produced in the crushing and grinding steps. Special consideration must be given to the stage reduction and .

09/03/2016 · The Beneficiation flowsheet shown with this study is particularly adapted to the concentration of tungsten ore in small tonnages. Tungsten minerals are generally in the friable class and therefore concentrating processes are hindered by the excess amount of fines produced in the crushing and grinding steps. Special consideration must be given to the stage reduction and .

Process Crushing Ores

Process Of Crushing Ores. Gold ore crushing process gold ore is one of the world s leading precious metal ores it not only plays an important role in the industry and in life but also the reserveof it is an important basis for maintaining financial stability therefore gold ore mining and beneficiation have great significance. View Details

Process Of Crushing Ores. Gold ore crushing process gold ore is one of the world s leading precious metal ores it not only plays an important role in the industry and in life but also the reserveof it is an important basis for maintaining financial stability therefore gold ore mining and beneficiation have great significance. View Details

ore crushing process metal ball

20tph copper ore crusher process. Oct 22, 2018· ball mill tph plant Guinee Ecologie. Gold ore crushing plant in Mala ball mill price tph important mining machinery silver, copper plants and mills for Silver Process Plant incliuding Jaw Crusher, Continuous Type Ball Mill manufacturer Gujarat, (1020) TPH (TPH means tons

20tph copper ore crusher process. Oct 22, 2018· ball mill tph plant Guinee Ecologie. Gold ore crushing plant in Mala ball mill price tph important mining machinery silver, copper plants and mills for Silver Process Plant incliuding Jaw Crusher, Continuous Type Ball Mill manufacturer Gujarat, (1020) TPH (TPH means tons

Crushing Iron Ores

Crushing Iron Ores. Even though the ilmenite ore is mined, crushing plant and grinding plant is made use of to obtain fineness ground crusher, impact crusher, cone crusher is widely made use of to minimize the big size ilmenite mill, raymond mill, vertical.

Crushing Iron Ores. Even though the ilmenite ore is mined, crushing plant and grinding plant is made use of to obtain fineness ground crusher, impact crusher, cone crusher is widely made use of to minimize the big size ilmenite mill, raymond mill, vertical.

「quenching cast steel balls for iron ores and copper ores」

Zinc ore called calamine is difficult to mix with the copper ore, however, and brass appears later in the archaeological record as well as being far less common than bronze. Return to top. Materials: Iron Steel. Iron is one of the commonest and cheapest metallic elements on the planet. In fact, by weight it makes up about 5% of the planet ...

Zinc ore called calamine is difficult to mix with the copper ore, however, and brass appears later in the archaeological record as well as being far less common than bronze. Return to top. Materials: Iron Steel. Iron is one of the commonest and cheapest metallic elements on the planet. In fact, by weight it makes up about 5% of the planet ...

الوظائف ذات الصلة

- فوائد طاحونة آلة

- كسارات الصخور المثبتة على عجلات السودان

- مخروط الحجر الجيري المحمول للبيع في اندونيسيا

- تكلفة معدات مناجم الحجر الجيري

- تصميم معمل تكرير الذهب

- آلات كتلة ذروة الشركات

- تستخدم الحجر محطم في الجزائر

- آلات تعدين الذهب الجزائر سوق

- عمان مصنع محطم

- أسعار كسارة الحجر الرملي صنع محجر الحجر

- stedman crushers model vsi

- alluvial centrifuge gold concentrator

- gnc tablet splitter crusher

- chemical processing magnesium mining

- synchronous chip sealerasphalt

- crushing screening por le

- concrete crushing machine company

- working principal of sand making machine

- motor for jaw crusher

- roller conveyor mm

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher