cement ball mill grinding

grinding ball | Magotteaux

Maxicrom® grinding ball You can grind to the maximum with Maxicrom® grinder ball. It revolutionizes coarse grinding. It is used in the first chamber of raw grinding mills and cement tube mills. It leads the way in process efficiency and wears well with little deformation. Fewer topups will be needed which makes for less safety risks for employees. It is available for raw grinding .

Maxicrom® grinding ball You can grind to the maximum with Maxicrom® grinder ball. It revolutionizes coarse grinding. It is used in the first chamber of raw grinding mills and cement tube mills. It leads the way in process efficiency and wears well with little deformation. Fewer topups will be needed which makes for less safety risks for employees. It is available for raw grinding .

Cement Grinding in Ball Mills and Vortex Layer Devices ...

Grinding cement in ball mills. The principle of the ball mill operation is simple: it consists of a rotating drum and grinding media (cylinders, balls etc). The material is placed into the drum which starts rotating. The grinding media and the substance both come in circular motion and at a certain point drop from the walls the bottom of the drum. The grinding is achieved by attrition ...

Grinding cement in ball mills. The principle of the ball mill operation is simple: it consists of a rotating drum and grinding media (cylinders, balls etc). The material is placed into the drum which starts rotating. The grinding media and the substance both come in circular motion and at a certain point drop from the walls the bottom of the drum. The grinding is achieved by attrition ...

cement ball mill grinding noise levels in ibels

Cement ball mill grinding noise levels in decibels the ball mill is key equipment in grinding industry especially in mineral ore dressing plants it is widely used for the cement the silie product new type building material fireproof get price 2019 grinding media balls grinding steel price. how to solve the noise of ball mill Machinery . The noise of ball mill is also a .

Cement ball mill grinding noise levels in decibels the ball mill is key equipment in grinding industry especially in mineral ore dressing plants it is widely used for the cement the silie product new type building material fireproof get price 2019 grinding media balls grinding steel price. how to solve the noise of ball mill Machinery . The noise of ball mill is also a .

Cement mill notebook

· In cement grinding the mill ventilation system fulfils two important functions, cooling the cement and removing the heat generated during the grinding process, and carrying part of the finished product out of the grinding area. It is well known that the energy used during the grinding process in ball mills is almost entirely converted into heat. An adequate mill ventilation system is .

· In cement grinding the mill ventilation system fulfils two important functions, cooling the cement and removing the heat generated during the grinding process, and carrying part of the finished product out of the grinding area. It is well known that the energy used during the grinding process in ball mills is almost entirely converted into heat. An adequate mill ventilation system is .

Industrial Solutions polysius ball mills

grinding brittle materials, such as cement, is still the ballfilled ball mill. The following types can be found: • singlecompartment mills, • twocompartment mills, • airswept mills as well as special designs. Costeffective, reliable and energysaving: with its highperformance range of ball mills for the grinding and drying of a wide variety of materials, thyssenkrupp Industrial ...

grinding brittle materials, such as cement, is still the ballfilled ball mill. The following types can be found: • singlecompartment mills, • twocompartment mills, • airswept mills as well as special designs. Costeffective, reliable and energysaving: with its highperformance range of ball mills for the grinding and drying of a wide variety of materials, thyssenkrupp Industrial ...

Ball mill maintenance for crushing and grinding of cement ...

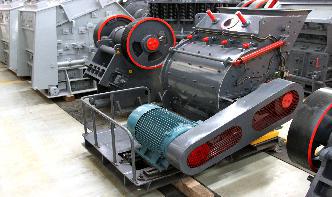

Ball mill maintenance for crushing and grinding of cement in cement plant Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill maintenance for crushing and grinding of cement in cement plant, quarry, aggregate, and different kinds of minerals.

Ball mill maintenance for crushing and grinding of cement in cement plant Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill maintenance for crushing and grinding of cement in cement plant, quarry, aggregate, and different kinds of minerals.

China Cement Mill Grinding Balls Manufacturer Supplier ...

Cement Mill Grinding Balls Manufacturers, Factory, Suppliers From China, We are also frequently hunting to determine relationship with new suppliers to .

Cement Mill Grinding Balls Manufacturers, Factory, Suppliers From China, We are also frequently hunting to determine relationship with new suppliers to .

Operations and maintenance training for ball mills

Ball mills are used for many appliions in cement production: raw meal grinding, coal and petcoke grinding as well as finish cement grinding. Each of these systems have their similarities and differences. This ball mill seminar is designed to train your personnel on the overall technology, operation and maintenance of your ball mill cement grinding system.

Ball mills are used for many appliions in cement production: raw meal grinding, coal and petcoke grinding as well as finish cement grinding. Each of these systems have their similarities and differences. This ball mill seminar is designed to train your personnel on the overall technology, operation and maintenance of your ball mill cement grinding system.

Mill equipment · Christian Pfeiffer

Cement industry Coal grinding Industrial minerals Mining and wet grinding ... Diaphragms, mill shell linings and grinding balls. The efficiency of ball mills can be significantly increased by the quality of your components. For this reason Christian Pfeiffer continues to develop their mill components, enriching the market again and again with their innovations. In the process, the .

Cement industry Coal grinding Industrial minerals Mining and wet grinding ... Diaphragms, mill shell linings and grinding balls. The efficiency of ball mills can be significantly increased by the quality of your components. For this reason Christian Pfeiffer continues to develop their mill components, enriching the market again and again with their innovations. In the process, the .

Some tests on the grinding of cement clinker with a ...

perimental stage of milling as applied to cement clinker. Ball mills . and . pebble mills have been used in a number of plants. ~hie . mill in its simplest conception consists of a cylinder revolTing around a horizontal axis with die plates arourid the circumference. ~he . grinding is done by steel balls. ~he . die ring is composed of chilled iron or steel pl tea arranged so that each laps the ...

perimental stage of milling as applied to cement clinker. Ball mills . and . pebble mills have been used in a number of plants. ~hie . mill in its simplest conception consists of a cylinder revolTing around a horizontal axis with die plates arourid the circumference. ~he . grinding is done by steel balls. ~he . die ring is composed of chilled iron or steel pl tea arranged so that each laps the ...

Ball Mill Simulation

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

Use Cement Ball Mill Grinding Cement Clinker | Cement Ball ...

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants. It is mainly used for grinding materials in cement clinker section. Cement ball mill is widely used in cement production, silie products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industries.

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants. It is mainly used for grinding materials in cement clinker section. Cement ball mill is widely used in cement production, silie products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industries.

cement ball mill

ball mill shell is rolled from steel plate,both ends equipped with supporting device;inside the shell linings are installed also that can host grinding media of different sizes. cement ball mill is running,grinding media loaded inside ball mill cylinder under the effect of centrifugal force and friction force rolls alongside the cylinder wall with crushed ore;when both of them ...

ball mill shell is rolled from steel plate,both ends equipped with supporting device;inside the shell linings are installed also that can host grinding media of different sizes. cement ball mill is running,grinding media loaded inside ball mill cylinder under the effect of centrifugal force and friction force rolls alongside the cylinder wall with crushed ore;when both of them ...

LOESCHEMILLS

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

Mills » Products » CEMTEC

Cement mills . Double chamber ball mills for the cement industry come in various designs: For bearings, either slide or slide shoe bearings can be chosen. Possible drives include gear rim/pinion, lateral, or central drives. If the processing material is wet, cement mills can also be equipped with a drying chamber. The drying chamber can be integrated into the mill or flangemounted to it. It ...

Cement mills . Double chamber ball mills for the cement industry come in various designs: For bearings, either slide or slide shoe bearings can be chosen. Possible drives include gear rim/pinion, lateral, or central drives. If the processing material is wet, cement mills can also be equipped with a drying chamber. The drying chamber can be integrated into the mill or flangemounted to it. It ...

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant ...

The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining powder grinding, and other grindable materials. Appliion: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: /H; Advantages. High ...

The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining powder grinding, and other grindable materials. Appliion: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: /H; Advantages. High ...

Back To The Grind: World Cement Grinding QA with Fives ...

· Nevertheless, in some instances, for raw meal grinding, the conventional ball mill remains a more appropriate solution, in particular in cases where there are large differences in the physical properties (grindability) of the different components in the raw mix or high abrasiveness of some components. With this perspective, Fives has developed a complete range of flash drying .

· Nevertheless, in some instances, for raw meal grinding, the conventional ball mill remains a more appropriate solution, in particular in cases where there are large differences in the physical properties (grindability) of the different components in the raw mix or high abrasiveness of some components. With this perspective, Fives has developed a complete range of flash drying .

75Mn Cement Mill Grinding Ball 10mm With Hammer Forging

High quality 75Mn Cement Mill Grinding Ball 10mm With Hammer Forging from China, China's leading 75Mn Cement Mill Grinding Ball product, with strict quality control Cement Mill Grinding Ball 10mm factories, producing high quality ANSI Cement Mill Grinding Ball products.

High quality 75Mn Cement Mill Grinding Ball 10mm With Hammer Forging from China, China's leading 75Mn Cement Mill Grinding Ball product, with strict quality control Cement Mill Grinding Ball 10mm factories, producing high quality ANSI Cement Mill Grinding Ball products.

Best energy consumption

· For cement grinding, the technology development away from ball mills has taken a different route. The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrinders. The main benefit was seen at lower Blaines as the first generation of presses suffered from stability .

· For cement grinding, the technology development away from ball mills has taken a different route. The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrinders. The main benefit was seen at lower Blaines as the first generation of presses suffered from stability .

Optimization of Cement Grinding Operation in Ball Mills ...

Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber. It is lined with classifyingtype mill shell liners and provided with finer ball charge. .

Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber. It is lined with classifyingtype mill shell liners and provided with finer ball charge. .

Cement Grinding Optimization

· Due to limitation of the mill's rotational speed, the smallest ball size is usually restricted to about 15 mm. Cement grinding using stirred mills (Pilevneli and Azizli, 1999) indies that using smaller media (58 mm range) improves grinding energy efficiency up to 50% using stirred mills. For specialized types of cement, which are finer than Portland, this figure would be .

· Due to limitation of the mill's rotational speed, the smallest ball size is usually restricted to about 15 mm. Cement grinding using stirred mills (Pilevneli and Azizli, 1999) indies that using smaller media (58 mm range) improves grinding energy efficiency up to 50% using stirred mills. For specialized types of cement, which are finer than Portland, this figure would be .

Effects of grinding aids on model parameters of a cement ...

· In this context, three different types of grinding aids were tested at various dosages in a cement plant and the impacts of grinding aids on model parameters of ball mill and air classifier were investigated. The results of this study are to be utilized in simulation of grinding circuits. In this way, by comparing the effects of doses of different types of grinding aids, the .

· In this context, three different types of grinding aids were tested at various dosages in a cement plant and the impacts of grinding aids on model parameters of ball mill and air classifier were investigated. The results of this study are to be utilized in simulation of grinding circuits. In this way, by comparing the effects of doses of different types of grinding aids, the .

Cement Finish Milling (Part 1: Introduction amp; History)

· Ball Mills. Although ball mills were first introduced in the 1860's, the main progress was made during the 1870's to 1900's in Germany, where its growing cement .

· Ball Mills. Although ball mills were first introduced in the 1860's, the main progress was made during the 1870's to 1900's in Germany, where its growing cement .

CALCULATION OF THE POWER DRAW OF DRY .

Key words: power draw, cement, dry grinding, ball mill INTRODUCTION Energy is the most important cost item in a cement plant. About 60% of the electricity consumption for cement production is used for grinding the raw material and cement clinker (Zhang et. al., 1988). Annual cement production is approximately billion tons and the grinding process consumes nearly .

Key words: power draw, cement, dry grinding, ball mill INTRODUCTION Energy is the most important cost item in a cement plant. About 60% of the electricity consumption for cement production is used for grinding the raw material and cement clinker (Zhang et. al., 1988). Annual cement production is approximately billion tons and the grinding process consumes nearly .

الوظائف ذات الصلة

- تعمل مطحنة الفحم

- صيانة طاحونة الفحم

- محطة تكسير الحجارة السويدية سعة 200 طن في الساعة

- كسارة متنقلة واحدة

- مطاحن الكاكاو مصر

- كسارة الحجر perhitungan rugi laba usaha

- كسارة الالات الثقيلة باتوبارا

- هيتاشي غسالة مصر

- كسارة فكية h36x25 dt

- كسارة الفحم لسعة 750 tph

- india new cement plant in assam equipment

- prix pour 350 tonnes dregon pierre usine de concasseur

- gold ore grinding machinegold ore grinding machine cost

- stone crusher posted

- stone crushers virgil in malaysia

- metallic minerals wikipedia

- photos of quarry stones in kenya

- roller coaster coal mining

- presentation on machinery used for aggrgates crushing

- distribuidores de molinos para la mineria en lima

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher