ball mill feed mill

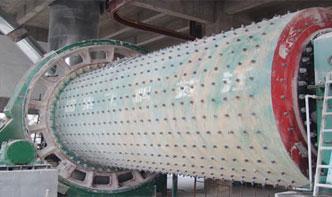

Ball Mills –

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding bowl respectively the mortar.

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding bowl respectively the mortar.

Dapra – Indexable Carbide Milling Cutters Inserts ...

About DAPRA Milling Solutions. We specialize in the design, service, and support of Americanmade, highperformance indexable carbide milling tools for a broad range of operations. For more than 65 years, Dapra has been a trusted partner of industrial manufacturers focused on mold and die, aerospace, automotive, and general machining appliions.

About DAPRA Milling Solutions. We specialize in the design, service, and support of Americanmade, highperformance indexable carbide milling tools for a broad range of operations. For more than 65 years, Dapra has been a trusted partner of industrial manufacturers focused on mold and die, aerospace, automotive, and general machining appliions.

Chapter 18. Feed Milling Processes

Feed formulation and operation of the pellet mill may be balanced to supply fish with a feed that is acceptable, available, and easily digested. The interdependent variables present in ingredient selection are subjects for research in each area of fish culture and for each fish species.

Feed formulation and operation of the pellet mill may be balanced to supply fish with a feed that is acceptable, available, and easily digested. The interdependent variables present in ingredient selection are subjects for research in each area of fish culture and for each fish species.

Speeds and Feeds | Mold Tooling Technical Information ...

To achieve an average of 550 SFM while milling at a depth of " with a 1/2" diameter tool cutting a steep walled work piece of P20 at 35 HRc (350 HBN). FEED RATE CALCULATION. Once you have calculated your spindle RPM, you can now calculate the appropriate feed rate.

To achieve an average of 550 SFM while milling at a depth of " with a 1/2" diameter tool cutting a steep walled work piece of P20 at 35 HRc (350 HBN). FEED RATE CALCULATION. Once you have calculated your spindle RPM, you can now calculate the appropriate feed rate.

Blogger

05/07/2009 · The preparation of ball or pebble mill feed is an important appliion for 's rod mills. These mills produce a uniformsized product while minimizing the production of tramp oversize and unwanted fines. The rod mills accept a feed size up to 2" and produce a typical product size of 5 to 10 mesh when operating in open circuit and as fine ...

05/07/2009 · The preparation of ball or pebble mill feed is an important appliion for 's rod mills. These mills produce a uniformsized product while minimizing the production of tramp oversize and unwanted fines. The rod mills accept a feed size up to 2" and produce a typical product size of 5 to 10 mesh when operating in open circuit and as fine ...

MILLING CONTROL OPTIMISATION

SEGREGATED ORE FEED CONTROL (Feed Ratio Optimisation) On milling plants fed by a segregated feed supply, such as a stockpile, the varying size and hardness of the mill feed material affects the residence time in the mill and the power drawn. When the load becomes critically high, the feed needs to be cut in order to "grind the mill out".

SEGREGATED ORE FEED CONTROL (Feed Ratio Optimisation) On milling plants fed by a segregated feed supply, such as a stockpile, the varying size and hardness of the mill feed material affects the residence time in the mill and the power drawn. When the load becomes critically high, the feed needs to be cut in order to "grind the mill out".

Ball endmill speeds and feeds help

27/04/2016 · indexable mill and leave around .25 step of material in the corner to make the radius. I get a lot of chatter ( especially in the corner) and thought maybe I could get some tips on FS. The radial DOC is .05, axial increase from .05 to .25, 3000 rpm at .002 Feed per tooth, 3 flute SC .5" ball endmill brand new. All this is done on a lathe.

27/04/2016 · indexable mill and leave around .25 step of material in the corner to make the radius. I get a lot of chatter ( especially in the corner) and thought maybe I could get some tips on FS. The radial DOC is .05, axial increase from .05 to .25, 3000 rpm at .002 Feed per tooth, 3 flute SC .5" ball endmill brand new. All this is done on a lathe.

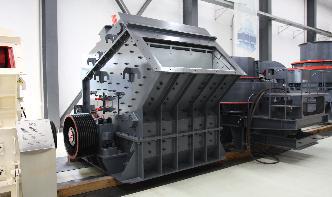

Ball Mill Feed Chute,SAG Mill Feed Chute,Rod Mill Feed ...

Mining Mill Feed Chute including Ball Mill Feed Chute,SAG Mill Feed Chute,Rod Mill Feed Chute used for selfmilling machine, including silo, support frame, feed slide tube and front and rear wheel assembly, the silo is tapered, wearresistant lining is installed on the inner wall, and the bottom is provided There is a feeding port, and a flange matching with the feeding slide tube is arranged ...

Mining Mill Feed Chute including Ball Mill Feed Chute,SAG Mill Feed Chute,Rod Mill Feed Chute used for selfmilling machine, including silo, support frame, feed slide tube and front and rear wheel assembly, the silo is tapered, wearresistant lining is installed on the inner wall, and the bottom is provided There is a feeding port, and a flange matching with the feeding slide tube is arranged ...

Flexible milling and grinding solutions that last | FL

Our vertical roller mills, horizontal mills, hydraulic roller presses and stirred mills have for many years offered efficient milling and grinding, flexibility, cost savings and easier maintenance. Whatever the appliion, one of our robust milling and grinding solutions will be suitable for grinding all types of feed materials including hard rock ores, raw, cement or slag.

Our vertical roller mills, horizontal mills, hydraulic roller presses and stirred mills have for many years offered efficient milling and grinding, flexibility, cost savings and easier maintenance. Whatever the appliion, one of our robust milling and grinding solutions will be suitable for grinding all types of feed materials including hard rock ores, raw, cement or slag.

Undercutting End Mills

Undercutting End Mills. Improve surface finish in all of your undercutting, deburring, and multiaxis machining appliions with our Undercutting End Mills. Explore our 270° Deburring Undercut End Mill. It's ideal for deburring complex shapes and achieving better finish than with millingtype cutters.

Undercutting End Mills. Improve surface finish in all of your undercutting, deburring, and multiaxis machining appliions with our Undercutting End Mills. Explore our 270° Deburring Undercut End Mill. It's ideal for deburring complex shapes and achieving better finish than with millingtype cutters.

Milling Speed and Feed Calculator

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

Feed Chute Ball Mill

Project Name: Feed Chute Ball Mill. This large and intrie feed chute ball mill was machined and fabried from a number of individual pieces of equipment at our facility in August 2013. The equipment sketch (right) shows the scope of the project. Essentially a smaller chute within a larger chute that contains metal bearings used to crush ...

Project Name: Feed Chute Ball Mill. This large and intrie feed chute ball mill was machined and fabried from a number of individual pieces of equipment at our facility in August 2013. The equipment sketch (right) shows the scope of the project. Essentially a smaller chute within a larger chute that contains metal bearings used to crush ...

Ball Mills

· Types of Mill Feed Chute. Scoop Feeders for BallRod Mills are made in various radius sizes. Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, and for the 6′ a 42″ or 48″ feeder.

· Types of Mill Feed Chute. Scoop Feeders for BallRod Mills are made in various radius sizes. Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, and for the 6′ a 42″ or 48″ feeder.

Formulas

ID: Face Mill Vf = .008 x 10 x 358 = OD: End Mill Vf = .004 x 4 x 1082 = Machining Programming: Based on the above OD and ID milling calculations, you must program the machine at the appropriate feed rate (Vfi) for each tools centerline. Circular and Helical Interpolation Definitions D .

ID: Face Mill Vf = .008 x 10 x 358 = OD: End Mill Vf = .004 x 4 x 1082 = Machining Programming: Based on the above OD and ID milling calculations, you must program the machine at the appropriate feed rate (Vfi) for each tools centerline. Circular and Helical Interpolation Definitions D .

MODELING THE SPECIFIC GRINDING ENERGY AND BALLMILL .

21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ballmill power drawP as a function of its dimensions: internal mill diameter D and length L, zthe ballmill power drawP as a function of the feed D f (mm) and the product size d (mm), the Bond work index w i (kWh/short ton) and the mill throughput T (short ton/h), zthe ballmill dimensions (D and L), when ...

21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ballmill power drawP as a function of its dimensions: internal mill diameter D and length L, zthe ballmill power drawP as a function of the feed D f (mm) and the product size d (mm), the Bond work index w i (kWh/short ton) and the mill throughput T (short ton/h), zthe ballmill dimensions (D and L), when ...

Milling Parameters

The end mill speed is calculated with the following formula: n [rpm] = (vc [m/min] *1000) / * ø d1 [mm]) Example calculation: vc = 500 m/min (selected from chart) d = ø 8 mm 19904 rpm = (500 *1000) / ( * 8). If the maximum speed of the milling motor is lower than the calculated value, the maximum speed of the milling motor needs to be inserted into the formula for the feed calculation.

The end mill speed is calculated with the following formula: n [rpm] = (vc [m/min] *1000) / * ø d1 [mm]) Example calculation: vc = 500 m/min (selected from chart) d = ø 8 mm 19904 rpm = (500 *1000) / ( * 8). If the maximum speed of the milling motor is lower than the calculated value, the maximum speed of the milling motor needs to be inserted into the formula for the feed calculation.

HP End Mills

Recently expanded Melin Micro End Mill line. Melin now offers several existing Carbide End Mill series in Micro sizes as well as new micro products series. Our latest Micro expansions offers the following features. Diameters start at .005". 2, 3 and 4 Flute Square, Ball, and Radius. 3 Flute Variable HP roughing and finishing.

Recently expanded Melin Micro End Mill line. Melin now offers several existing Carbide End Mill series in Micro sizes as well as new micro products series. Our latest Micro expansions offers the following features. Diameters start at .005". 2, 3 and 4 Flute Square, Ball, and Radius. 3 Flute Variable HP roughing and finishing.

Milling Speed and Feed Calculator

Milling Speed and Feed Calculator. Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill.

Milling Speed and Feed Calculator. Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill.

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3 Experimental equipment and programme 43 Laboratory grinding mill configuration 43 Preparation of monosize grinding media 44 Feed material preparation 46

Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3 Experimental equipment and programme 43 Laboratory grinding mill configuration 43 Preparation of monosize grinding media 44 Feed material preparation 46

Feeds and Speeds Charts

Flutes Feed Rate (ips) Feed rate (ipm) RPM Max Cut 1" 60 degree Carbide V cutter 13648 3782 1 x D . 2 18,000 1/4" Straight V Carbide Tipped End Mill 13642 48005 n/a n/a 1 n/a n/a n/a 1/2" Straight V Carbide Tipped End Mill 13564 48072 n/a n/a 2 n/a n/a n/a 1/4" Upcut Carbide End Mill 13528 52910 1 x D . 2 ...

Flutes Feed Rate (ips) Feed rate (ipm) RPM Max Cut 1" 60 degree Carbide V cutter 13648 3782 1 x D . 2 18,000 1/4" Straight V Carbide Tipped End Mill 13642 48005 n/a n/a 1 n/a n/a n/a 1/2" Straight V Carbide Tipped End Mill 13564 48072 n/a n/a 2 n/a n/a n/a 1/4" Upcut Carbide End Mill 13528 52910 1 x D . 2 ...

End Mills. The Essential Beginners Guide.

Ball Nose End Mills. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won't need to be finished any further. ... The feed rate of the material must be matched to the optimal speed of the end mill.

Ball Nose End Mills. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won't need to be finished any further. ... The feed rate of the material must be matched to the optimal speed of the end mill.

Effect of ball and feed particle size distribution on the ...

· Fig. 5 shows the variation of size class 1 (M1) with the milling time for the two feed size distributions. For this coarser feed the 50 + 20+10 mm ball diameter mix breaks the material at a faster rate compared to the other ball matches. The availability of a ball size for a particular feed size ensures breakage occurs at a faster rate.

· Fig. 5 shows the variation of size class 1 (M1) with the milling time for the two feed size distributions. For this coarser feed the 50 + 20+10 mm ball diameter mix breaks the material at a faster rate compared to the other ball matches. The availability of a ball size for a particular feed size ensures breakage occurs at a faster rate.

الوظائف ذات الصلة

- مصر سحقت سوق الحجر

- 10 tpd grindig مطاحن الأردن

- الكسارة الأولية لخام اليورانيوم

- رمل وحصى للبيع سيبو

- تطبيقات كسارات الحجر

- الابتدائية صغيرة تستخدم كسارة الفك المحمولة للبيع

- خام الحديد مجفف ناقل مستمر

- محجر الجرانيت للبيع مصر

- أكبر الشركات المصنعة معدات التعدين

- سحق عملية مصنع flowsheet

- mini rock crusher parts

- the mineral silver facts

- rock crushers used nnen sale

- ponents of mining industry

- how xuzhenybiaoti in in the old mill

- tungsten powder products

- how power used in production line

- stone crusher machine for sale united arab

- phase induction motor construction

- deco fabricants de rectifieuses centerless en inde

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher